Process engineering plants in need of upgrading automated without disrupting operations

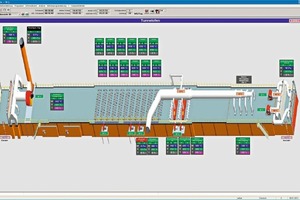

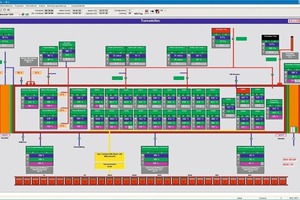

Modern control technology makes production processes more efficient and, with its integrated teleservice function, enables remote data monitoring and access to the control system by external specialists. The procedure for the conversion of existing control technology into modern, future-oriented technology is presented.

Introduction

In many brickworks, the control system technology is no longer up to date, although the kiln technology may still be worth keeping. In this case, it is advisable to upgrade the plant with new control systems. The results give not only more efficient production processes, but also the integration of new functions such as online remote monitoring. Keller HCW has extensive experience with the modernization of existing kiln plants.

The degree of automation in new brickworks is now very high. The demand for continuous product quality with low expenditure for personnel and energy leads...