Simulating the thermal properties of clay brick masonry and wall elements

Sabo S.A. is regarded as one of the pioneers of the heavy clay industry and can look back on a 35-year success story as a supplier of turnkey solutions for this industry. Following in this tradition, Sabo S.A., in collaboration with the National Technical University of Athens, is offering clay brick manufacturers the possibility to calculate the thermal properties of all types of building material profiles or masonry before these are tested in real building conditions.

Introduction

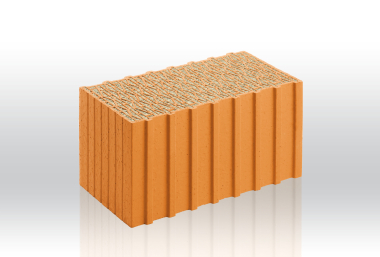

In recent years, energy consulting has become increasingly important in the construction sector. Statutory and efficiency requirements for newbuilds necessitate the use of sustainable products of high quality. This issue has forced engineers to look for masonry materials with high thermal insulation. Clay bricks offer an optimum wall building material solution for most construction projects. In response to the current demand, the machine engineering company Sabo S.A., which also supplies turnkey solutions, is collaborating with the National Technical University of Athens to offer brickmakers support and solutions for improving their masonry blocks.

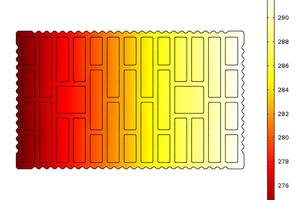

The thermal performance achieved is determined in a computer-based calculation with finite element analysis (FA) by NTUA as well as calculation of the U value of the wall according to European standards.

Methods

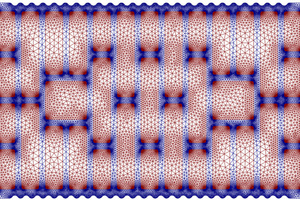

The thermal performance of clay bricks can be modelled directly using computational fluid dynamics (CFD) simulations or a simplified method based on EN 1745, EN ISO 10211:2007 and EN ISO 6946 standards. In CFD, the governing partial equations (in a differential form) are discretized (converted to algebraic form) so that they can be solved using direct or iterative linear solvers.

Model for the properties of clay bricks

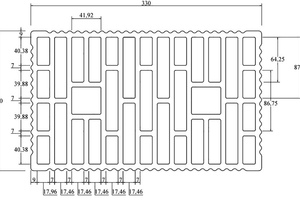

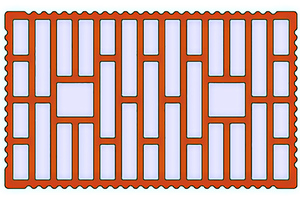

In the second calculation approach, which is a simplified method based on the standards, the main difficulty is to calculate the effective properties of the air cavities especially when they are not rectangular. In this case, after the transportation of the non-rectangular cavities into rectangular ones, the equivalent thermal conductivity can be calculated from the convective heat transfer coefficient (ha) and the radiative heat transfer coefficient (hr). In »Table 1, the properties of clay and air considered as homogeneous fluid continua are presented.

Masonry performance

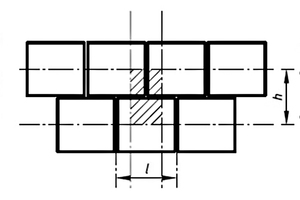

The thermal transmittance of masonry built can be modelled directly using the thermal performance of clay bricks. All the components used for an actual built wall (mortar joints between the materials, plaster on the internal and external wall surfaces), are taken into consideration in the modelling, using a simplified method based on EN-1745, EN ISO 10211:2007 as follows:

where Umas,act is the thermal transmittance of masonry made from units with height hunit in (W m-2 K-1), hunit,act is the actual height of the unit in mm and hmor,act is the actual height of the mortar joint in mm. hact is hunit,act plus hmor,act in mm. (see »5).

Sabo S.A., in collaboration with the National Technical University of Athens, is offering brickmakers the possibility to calculate the thermal properties of all types of building material profiles or masonry before these are tested in real building conditions.

Sabo S.A.

www.sabo.gr