Use of crushed brick dust in cement production

Fine-grained, recycled aggregates (crusher dust) have not yet been defined as principal constituents of cement in DIN EN 197-1.

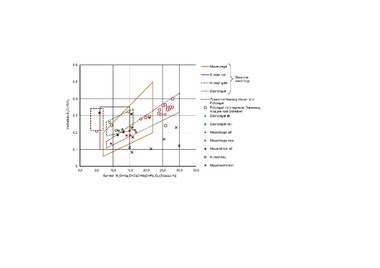

Cement containing crushed brick dust as its main constituent therefore requires certification. In addition to a technical analysis of properties in accordance with DIN EN 196-1 and DIN EN 197-1 plus durability testing of the concrete, crusher dust must also adhere to environmentally relevant eluate and particulate emission parameters. The purpose of the investigations conducted in the “R-concrete“ research project (//www.r-beton.de" target="_blank" >www.r-beton.de:www.r-beton.de) was to develop guidelines for the use of crushed brick dust in the production of cement. The tested cements were produced by mixing 90 or 70 mass-% CEM I 42.5 R or 52.5 R with 10 or 30 mass-% crushed brick dust. Crusher-dust varieties of concrete, masonry and roof tile rubble, track ballast and railway sleepers were used. The tested cements conformed to strength classes 42.5 N through 52.5 R. The certification evaluation criteria for concrete durability were fulfilled using cements with up to 10% crusher dust by mass. The various crusher dusts all satisfied the environmental analysis requirements laid out in DIN 4226-101.

Dr.-Ing. Christoph Müller, VDZ gGmbH