ceramitec 2018 inspires good climate for investment in the ceramics industry

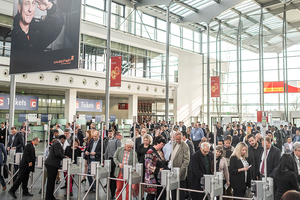

The international ceramics industry was in a very good mood for investments in Munich at ceramitec 2018 from 10 to 13 April, as summed up by Messe München, the trade fair organizer. The key international trade show for the ceramics and powder metallurgy sector was attended by around 15 000 participants wanting to find out about future-oriented topics for the industry.

“ceramitec 2018 was a great success”, says Gerhard Gerritzen, Member of the Management Board of Messe München. “I am particularly pleased with the fact that the positive trend indicated by the ceramitec industry barometer, a survey we conducted among industry representatives during the run-up to the trade show to learn more about their investment behaviour, has been confirmed at the event. The exhibitors were able to transact good business deals, received high-quality visitors at their stands and established a great number of new contacts.” The event has thus proven its reputation as an international key trade show once again. “And all this even though the conditions were slightly difficult – apart from this year’s unusually packed trade show calendar, we had a strike at Munich Airport on the opening day”, adds Gerritzen.

Focus on digitalization

After a few rather challenging years, the industry looked ahead with optimism at ceramitec 2018. Accordingly, the future-oriented topics of digitalization and Industry 4.0 determined the professional exchange at the trade show.

In view of this development, the importance of ceramitec is increasing even further:

“The dominating topic in the field of ceramics is digitalization. This is all about highly automated processes facilitating efficient manufacturing for customer-specific solutions”, explains Dr. Jürgen Blumm, Chairman of the ceramitec Advisory Board and Managing Director at Netzsch Gerätebau GmbH.

“Particularly in times of digitalization, meeting people personally at trade shows like ceramitec is more important than ever before to define the right interfaces between suppliers and customers. The information density here is higher than anywhere else”, says Joachim Heym, Managing Director at Schunk Ingenieurkeramik GmbH.

Very high degree of internationality among exhibitors and visitors

Boasting over 15 000 participants, the event was also once again very well received. In this context, ceramitec asserted its position as the international meeting point for the ceramics industry. Accordingly, the 633 exhibitors came from 38 countries (2015: 617 exhibitors from 37 countries). After Germany, the countries with the highest representation were Italy, China, France, Spain and Portugal. On the visitors’ side, the proportion of international guests, which amounted to around 60 percent, was higher than average again. Most of the international visitors came from countries like Italy, Austria, France, Turkey, China and Russia. The international diversity contributed to the exhibitors’ satisfaction.

“We rate our participation at ceramitec again as very positive. We could exchange ideas and information with many existing customers and numerous potential new customers and had very good business meetings”, says Marco Lanfranco, COO at Bongioanni Macchine, the Italian supplier of machinery for clay bricks and roofing tiles and one of the most important exhibitors in the heavy clay ceramics segment.

However, such an international industry is also influenced by general political and economic conditions. The effects of the different international conflicts and protectionist tendencies were therefore the subject of intensive discussions at the trade show: “Especially the areas of mechanical engineering and plant engineering in the ceramics segment are very international in their orientation and would therefore be affected by possible trade barriers”, summarizes Dr. Jürgen Blumm.

Heavy Clay Day

For the fourth time now, Zi Brick and Tile Industry International presented the Heavy Clay Day at ceramitec. The efficient utilization of resources is one of the big challenges for the heavy clay ceramics industry, especially with regard to energy. For this reason, the dominant issue at the event was again energy saving in the manufacture of clay bricks and roofing tiles.

The day was kicked off by Thomas Wagner, Händle GmbH Maschinen und Anlagenbau, who in his talk entitled “Roofing tile production in a new dimension” presented Händle’s new Nova III roofing tile press with all its new features. The Nova III is designed for stiffer pressing, a higher interlock and complex roofing tile shapes, boasting high efficiency. It can be used to press up to four large-size roofing tiles. The stable design guarantees the exact positioning of the clay slugs and therefore a perfect finished product.

In the second talk “Short-term heat storage in the clay brick and tile industry”, Dr.-Ing. Dipl.-Wirt.-Ing. (FH) Anne Tretau, Brick and Tile Research Institute Regd, presented the findings of a joint research project. The interim storage of energy is one possibility to utilize the waste heat produced during clay brick and roofing tile manufacture. The studied buffer storage of facing bricks was designed based on a simulation model.

An overview of the possibilities to save energy in the clay brick and tile manufacturing process was given by Prof. Dr.-Ing. Christian Schäffer, Koblenz University of Applied Sciences – Höhr-Grenzhausen. He presented the “Decoupling of the kiln-dryer heat system and the exergetic and energetic optimization of a tunnel kiln”. Referencing exemplary optimization projects in several existing plants, Schäffer showed that enormous energy cost savings are possible, e.g. with the decoupling of kiln and dryer, the utilization of exhaust energy and the reduction of exit losses.

Dr.-Ing. Stefan Vogt, Robert Thomas Metall- und Elektro-werke GmbH & Co. KG, also addressed possibilities for energy saving. In his observations on the “Advantages and boundary conditions of fast firing bricks”, he gave an overview on solutions that have already been realized and presented the optimum preconditions for fast firing.

Heavy Clay Day concluded with a presentation by Stefan Reichert, Keller HCW GmbH, on “Digitalization in the brick and tile industry”. Reichert presented the newly developed App KBIS – a new digital information platform. Operators can use this to obtain production and status data on their plants in line with their needs as well as maintenance tips and recommendations on process optimization.

Lingl receives Zi Award for Best Service Supplier 2018

Working in cooperation with Messe München, Zi Brick and Tile Industry presented the Zi Award Best Service Supplier 2018 during the Heavy Clay Day at ceramitec 2018.

The award was sponsored by the companies Keller HCW GmbH, Petersen Service GmbH, Refratechnik Ceramics GmbH, Rehart GmbH, Stephan Schmidt KG and Hans Lingl Anlagenbau und Verfahrenstechnik GmbH & Co. KG.

According to the vote of Zi readers from 17 countries worldwide, awards were presented to those suppliers who offer their customers the best service. In addition to machine and plant engineering companies, raw materials suppliers and other industry participants were nominated.

Winner of the Zi Award Best Service Supplier 2018 was Hans Lingl Anlagenbau und Verfahrenstechnik GmbH & Co. KG. Gottfried Hartmann received the award as the best employee.

Second place went to Händle GmbH Maschinen und Anlagenbau, best employee here was Michael Gulden.

Rehart GmbH with its employee Nico Napolitano was voted into third place.

Of all the participants in the subsequent draw, the name of Max Venus was drawn, who won the 250 € voucher for the Hofbräuhaus.

Digitalization in heavy clay ceramics

This year, the plant and machine engineering companies supplying the brick and tile industry presented their products and services in Hall B5, while the raw material and engobe suppliers were in Hall A6. At this point, we can present just a very small selection.

ceramitec 2018 was again not a trade fair for huge innovations. In Munich the industry meets to share international experience, Wednesday and Thursday being the most popular days, with lots of very busy stands. The general tenor was that major projects were currently lacking in heavy clay ceramics. The plant engineers reported lots of relatively small orders to optimize, modernize or extend plants. There was no new boom market like North Africa and Algeria have been for a long time.

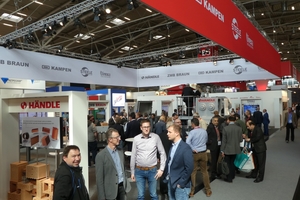

Together with its partners ZMB Braun, Kampen, Steele and Direxa, Händle was one of the few exhibitors to show large exhibits at its stand, one highlight was the new roller mill Gamma, the Extruder Futura II and a die washing machine Clean-Tech. Händle’s Managing Director Gerhard Fischer reported that two new Nova III roofing tile presses have been sold to the Röben’s plant in Poland. Kampen outlined its know-how as a die specialist, for example, for complicated cross-sections for facing bricks. At the always well-frequented stand of Händle and its partners, visitors had the opportunity to find out about the Group’s comprehensive range.

Lingl has adapted its strategy to current market conditions, as Sales Manager Karl Liedel explained. As large-scale projects are currently rare in heavy clay ceramics, the company is focussing on renovation, partial reconditioning and upgrades. In this respect, customer goals such as high product quality and cost efficiency as well as low energy consumption are realized. Speed and flexibility were, he explained, in demand as projects have to be realized ever faster. Lingl has already successfully positioned itself in new branches of business like ceramic sanitaryware and the timber industry.

Keller presented itself with its reorganized company structure and digitalization as its keynote. The App KBIS was received with great interest. With KBIS the customer can call up real-time data on its plant and is alerted, for example, to maintenance requirements.

The specialist for refractory solutions, Refratechnik Ceramics GmbH, showed with RefraBoard an innovation on the basis of renewable resources. The CO2-neutral product line combines extreme refractoriness with high insulation and high compressive strengths. The integrated firing frame for roofing tile firing met with great interest from the roofing tile manufacturers.

At the stand of the dryer specialist Rotho, we were informed that new support units for the dryer are being supplied to Röben Poland as part of the modernization project.

The Brick and Tile Research Institute Regd announced its new cooperation with the Forschungsinstitut für anorganische Werkstoffe – Glas/Keramik GmbH.

TES – Tecno Extrusion System was a highlight at Bongioanni, the Italian machine engineering company. This was developed for the optimization of the shaping process. The user-friendly, intuitive and easy-to-understand touch-screen interface was inspired by Industry 4.0. TES is used for the analysis and optimization of the product as well as the production process. This is designed to reduce energy and maintenance costs. Another topic is the use of FEM in roofing tile presses.

Bernini Impianti showed, for instance, solutions for use of alternative fuels, e.g. biomass. The easy changeover of different fuels, solid, liquid and gaseous fuels and their combination is another topic of the burner specialist. Presented were, amongst other things, easy-to-operate fuel preparation and metering equipment with which it is possible to switch between different fuels.

FB Engineering reported on its just completed projects, for instance, in France. Here for a well-known roofing tile manufacturer, a roofing tile press for complex shapes has been supplied.

Bedeschi President Rino Bedeschi presented the current projects of the Italian plant engineering company, which is celebrating its 110th anniversary in 2018. For the brick and tile industry, Bedeschi presented, for example, a system for the prefabrication of brick walls, which has been installed at a Czech brick manufacturer’s plant. Bedeschi is also following the trend of filling clay blocks with insulating materials and includes an installation for this in its range of equipment and machinery.

“JoyTeach”, a universal robot console that comprises an industry touch-pad and two joysticks and can be used for all industry applications, was a highlight at the Cleia stand. This box can be used quickly and intuitively to simplify robot programming.

The raw material and engobe/glaze manufacturers in Hall A6 exhibited their product ranges for discussion. Besides individual clays, blended raw materials are available. In surface design, architects are attaching great importance to individuality. The engobe and glaze manufacturers can meet this requirement with a wide range of colours. Here too, consulting, joint development and service with brick and roofing tile manufacturers are an important topic.

Dr. Matthias Frederichs, General Secretary of the Federal German Association of the Brick and Tile Industry Regd, informed visitors to the trade fair of news in the industry. In a discussion with representatives of the Peruvian Brick Association ALACEP, which was only founded one year ago, Frederichs explained the work of the German association to his Peruvian colleagues. Interesting were topics such as the degree of organization in Germany, the current and future core activities in the German association’s work and possibilities to get the attention of policy-makers, especially with regard to production-related topics. The Peruvian Association is interested in cooperation for know-how transfer (including training in technology and association work).

“Forgestal has again attended ceramitec as it has over the last 20 years. For us, it is the most important exhibition in the world on equipment for the brick and tile industry. This has been confirmed this year with a remarkable number of visits from companies around the world. At the moment, it is not the best time for some traditional brick markets like Algeria, Spain or Russia. In consequence, there have been fewer visitors from these countries. We have also noticed fewer visitors from Asia. On the other hand, we have had interesting and fruitful meetings with visitors and customers from Europe, South America and other regions. For Forgestal, the opportunity to interact with many exhibitors who are customers or colleagues, to talk about projects in progress or about the situation of our industry is also very important“, says Paco Palanques, Forgestal.

Comprehensive conference programme and 93rd Annual Meeting of the German Ceramic Society DKG

ceramitec was accompanied by a comprehensive conference programme. During various information days, visitors could obtain information on current developments and issues at a variety of lectures and discussion panels. Simultaneously with ceramitec, the 93rd Annual Meeting of the German Ceramic Society DKG and Symposium on High-Performance Ceramics by DKG and DGM, and the General Meeting of the Association of the German Ceramic Industry VKI took place on the exhibition grounds. Thus, the entire national and international ceramics scene had gathered in Munich.

In cooperation with the CIM Expert Group, Fraunhofer Advancer, IAPK Aachen, FGK Höhr-Grenzhausen, DKG, think ceramics/BVK, Ceramic Applications presented for the first time the “Best Component Award Technical Ceramics” with the aim of raising the profile of this group of products. Technically sophisticated solutions are often “hidden champions”, because they are generally fitted in complex systems, but often determine performance. The presentation of the award was held on 12 April 2018 at the ceramitec Forum to conclude Technical Ceramics Day. The winners were then celebrated at the Ceramic Applications stand.

The next ceramitec is scheduled for November 2021 in Munich.

ceramitec

www.ceramitec.com