CO2-negative Pirrouet façade block wins German Sustainability Award

Brick manufacturer Vandersanden receives prestigious award in the climate transformation field 06.11.2024The German Sustainability Award (DNP) is the largest award for ecological and social commitment in Europe. The decision has now been made: At the 17th DNP awards ceremony on 28 and 29 November, brick manufacturer Vandersanden will receive the DNP for its innovative CO2-negative facing brick Pirrouet.

This makes the Belgian family business Vandersanden the only brick manufacturer to score points with the DNP judges for its sustainability ambitions. This is because the brick experts absorb carbon dioxide from the atmosphere with the new Pirrouet® facade brick and bind it permanently. The highlight: the Belgians run the entire production process on renewable energy. The production of Pirrouet bricks binds a total of 2,280 tonnes of CO2 per year; this corresponds to the annual CO2 absorption of 114,000 mature trees. This is a great opportunity for the entire building materials industry in Europe.

Pirrouet prevails against hundreds of participants

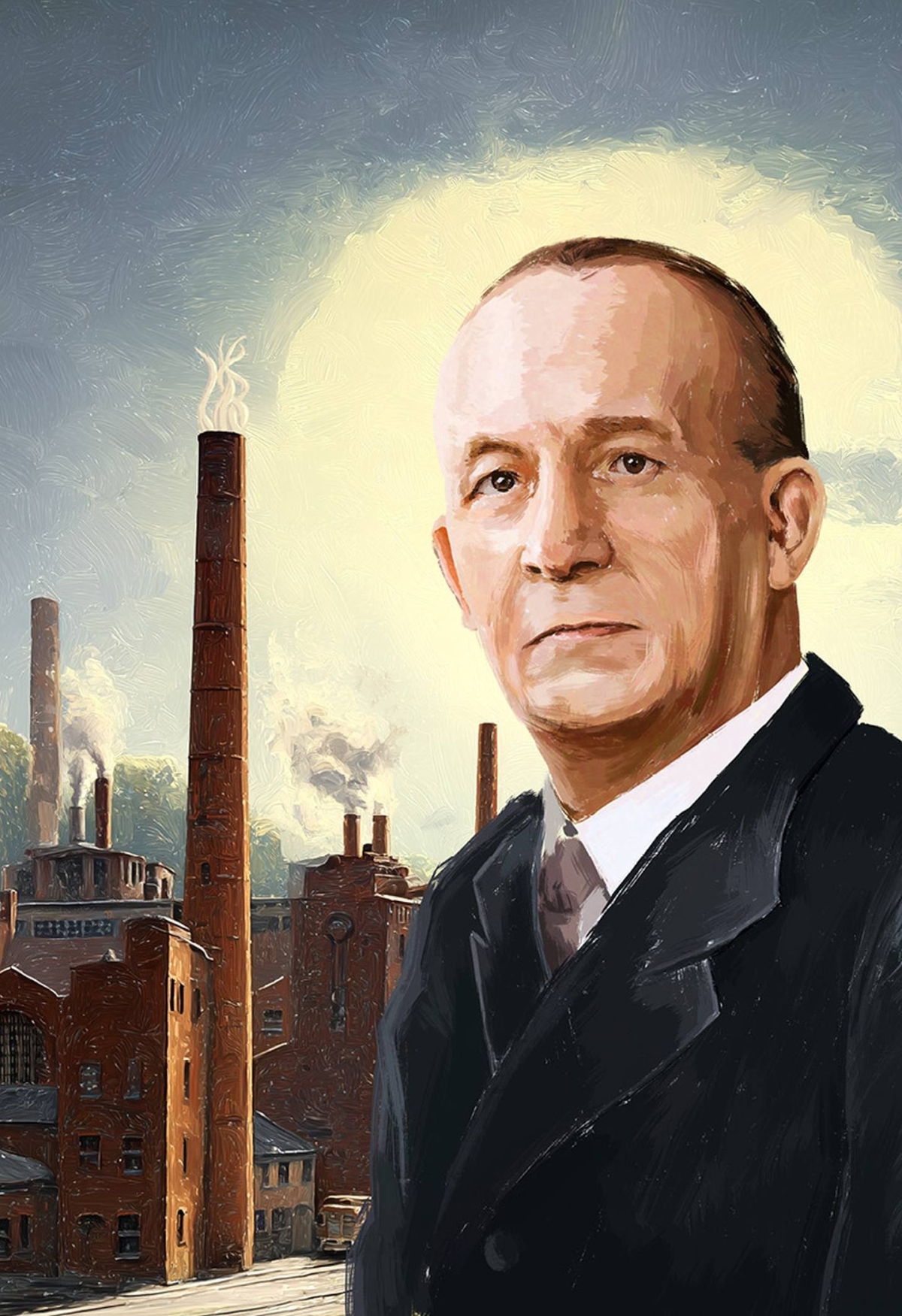

Out of a total of 272 participants in the products category in five sub-categories, 30 made it to the final in the climate transformation field. Vandersanden was awarded the DNP for its CO2-negative Pirrouet façade brick in the climate transformation field. Johan Deburchgrave, CEO of Vandersanden: "I'm really looking forward to the event in Düsseldorf. The fact that we have won this high-calibre award is a real accolade for us. We are thrilled that our efforts for a better climate have been honoured at this level."

Unique: facing brick absorbs carbon dioxide

Pirrouet is the first CO2-negative facing brick on the market In September 2024, Vandersanden, the largest family-run brick manufacturer in Europe, opened its first Pirrouet plant in Lanklaar, Belgium. Vandersanden invested a total of 32.5 million euros in the plant. At full capacity, the plant produces 20 million of the CO2-negative Pirrouet facing bricks per year. Vandersanden CEO Deburchgrave: "The initial situation was: How can we manufacture products that have lower CO2 emissions? Everything could be questioned. And so, with Pirrouet, we developed a product that is not only CO2-neutral, but also extracts more carbon dioxide from the atmosphere during its production process and life cycle than it emits. This puts us alone in the entire building materials industry."

Pirrouet: off to a sustainable start with eleven colours

"Our Pirrouet launch range includes façade tiles in eleven colours with a delicately structured, elegant surface texture," says Vandersanden CEO Deburchgrave. "This means that in addition to the important aspect of sustainability, we also have an aesthetic component that is no less relevant for successfully positioning Pirrouet on the European market. And I'm sure that winning the DNP will be an excellent way for us to achieve this."

About the German Sustainability Award

The German Sustainability Award is the national award for excellence in sustainability in all sectors. With six competitions, including the first for health, over 1,300 applicants and 3,000 guests at the events, the award is the largest of its kind in Europe. The award is presented by the Stiftung Deutscher Nachhaltigkeitspreis e.V. (German Sustainability Award Foundation) in cooperation with the German government, leading municipal associations, business associations, civil society organisations and research institutions. The award ceremony is held at the German Sustainability Day in Düsseldorf, the most visited annual communication platform on the subject of sustainable development.

About Pirrouet

Pirrouet is the first CO2-negative and recyclable cladding brick on the market. In the production of Pirrouet, CO2 from the atmosphere forms a chemical compound with calcium-containing materials of purified mineral residues from the steel industry. This combination produces our very robust facing bricks. During the production process, 60 kg of CO2 per tonne of Pirrouet® is absorbed and permanently bound in the brick.

This process, known as carbonation, in which calcium-containing materials (Ca) react with carbon dioxide (CO2) to form calcium carbonate (CaCO3). Calcium carbonate occurs worldwide in nature and is an important factor for natural CO2 storage.

As we produce Pirrouet from up to 80 per cent residual materials from the steel industry (Carbinox and Stinox), we only need around 20 per cent primary raw materials such as sand, water and dyes, thus significantly reducing the amount of waste. Further information: www.vandersanden.com/de-de/pirrouet