The clay brick and tile industry in Tunisia – a brief overview

Tunisian clay brick and tile industry

Technologies that in traditional brick and tile making countries have only been recognized as expedient only in isolated cases, for example equipment for plant-internal power generation, are often funded by governmental or semi-governmental offices, sometimes without careful analysis of the technical issues. In international comparison the clay brick and tile industry in Tunisia cannot be regarded as very competitive in terms of technology as the product quality in particular must be improved considerably.

Tunisia has set itself a very ambitious energy programme: By 2016, according to details from the ANME, 1 000 MW electric energy, including 200 MW from renewable sources, are to be exported to Europe. At the same time, the total energy consumption of the country is to be lowered by 22%. The question of how these goals are to be achieved remains open.

Produced are mainly solid bricks, which make up around 10% of the market, vertically perforated bricks with two or three rows of equally sized perforations as well as products for brick floors.

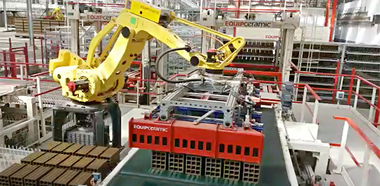

In Tunisia 129 brickworks are currently in operation («Table 1), which employ around 4 000 people. The annual production capacity of below 7.25 mill. tonnes in the year 2006 increased to over 10.5 mill. tonnes in the year 2010. Plants with a capacity < 0.6 mill. t/year are under construction. The published production figures indicate an average capacity utilization of around 70%.

The energy input of the Tunisian brick and tile industry for the year 2010 is specified for gas-fired plants at around 39 to 48 Nm3 per thousand bricks. For oil-fired plants, the consumption should be at around 35 to 45 kg/t. The power consumption is estimated at 30 to 40 kWh/t. The figures are based on data from the CTMCCV.