20 years of material research and testing at MFPA in Weimar

Today’s MFPA Weimar evolved from the liquidation of all institutions at the erstwhile GDR Academy of Architecture as per Germany’s 1990 Unification Treaty. Accommodating the reunified country’s industrial research and testing needs, the Materialforschungs- und -prüfanstalt was established in Thuringia as that German state’s official material test institute. The new MFPA was conceived and structured along the lines of the Bauhaus-Universität sub-faculties and intermeshed with the university’s human resources by appointing professors as department heads. Most of the new entity’s staff was made up of employees from the former materials institute.

Today’s MFPA is a technical service provider for testing, monitoring and certifying construction and insulation products and for analysing the condition of and damage to structures and components. In addition, the institute sees itself as an independent research facility with focus on the material sciences. Special value is attached to engaging in collaborative research with middle-market companies on joint projects.

Soon after MFPA was established, the discipline building physics, which deals primarily with the hygrothermal properties of materials, began using the existing double climate chambers for climatic and thermotechnical testing of building components. Now, i. e., since 1994, thermotechnical tests performed by MFPA are recognized by DIBt (German institute for structural engineering) on the basis of proven competence and a positive rating by the competent panel of experts. Since 2002, when the testing, inspection and certification bodies of the dissolved Institute of Structural and Coarse Ceramics in Weimar were incorporated, MFPA has the requisite capacity for complete quality monitoring of heavy clay products, including supervision of in-plant production control and product testing plus certification.

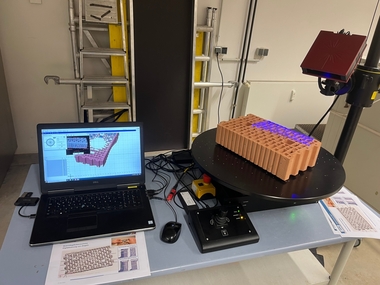

Key areas of technical services in heavy clay testing centre on determining the thermal resistance of vertically perforated clay units in accordance with DIN 52611 and/or DIN EN 1934 and the thermal conductivity of heavy clay materials employed for walls in accordance with DIN 52612 and/or DIN EN 12664. Thermal testing of masonry is performed on duly prepared 1.5 m x 1.5 m walls as test specimens. The measurements are performed with a heat flow meter apparatus for determination of thermal resistance (»1).

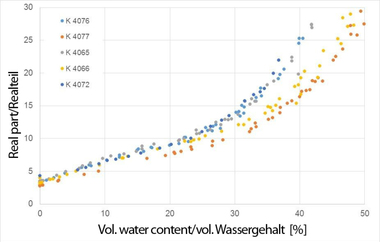

Knowledge of net apparent density alone does not suffice for characterizing the thermal behaviour of brick bodies. Their conductivity must also be known, especially in the case of vertically perforated clay units filled with tabular insulating material. The specimens consist of meticulously wet-ground and dried outer longitudinal webs taken from the bricks, and testing is executed using a single-plate or double-plate guarded hot plate apparatus. In parallel with thermal testing, MFPA’s modernly equipped laboratories also investigate diverse additional brick parameters (»2).

Other focal areas have since been added to the specialty field, e. g., determination of thermal resistance by means of FEM modelling and numerical simulation of thermally optimized masonry.

In addition to ascertaining the hygrothermal properties of structural clay products and insulating materials under laboratory conditions, the MFPA services spectrum also includes such on-site investigations as thermography, determination of building leaktightness by means of differential pressure measurements and damage analysis of brick masonry and structural clay products per se.

Student and trainee mentoring and the continued education of specialized personnel in diverse areas round out the institute’s broad range of activities.

Long since known for more than just testing bricks, MFPA Weimar is an accredited test laboratory providing any number of areas in the construction sector with research assistance and other services spanning an arc from geotechnical investigations and testing of building materials to environmental analyses and calibration of measuring instruments.

Materialforschungs- und -prüfanstalt Weimar is well staffed, stocked and equipped for the future and as a reliable partner to the brick and tile industry.

Paul Rieger and Alexander Freyburg