Standards and deviations - Information event of the Güteschutz Ziegel 2024

On April 17 and 18 2024 the members of Güteschutz Ziegel e. V. (brick quality protection association), the relevant committees and testing bodies as well as employees of the brickworks were drawn to the Materials Research and Testing Institute (MFPA) in Weimar, Germany. The Güteschutz Ziegel had invited to the yearly information event. As usual, the program included information on the current status of product and testing standards, the latest building regulations and helpful information on ceramic building products. In contrast to previous events, this time the program included a practical section, practicing testing methods.

The program on both days was led by the head of Güte-schutz Ziegel, Frank Pohle, who welcomed the participants on the first day.

Practical block for perforated heavy clay building materials

The first practical part focused on perforated heavy clay building materials. The participants worked in four groups at four stations in different rooms of the MFPA. One station dealt with the correct measurement of vertically perforated bricks. The participants were allowed to use calipers to take measurements themselves. The variance of the measurement results was astonishing, as was the extent to which measuring processes require a lot of preconditions. Methods for determining the density of perforated stones was also demonstrated and explained.

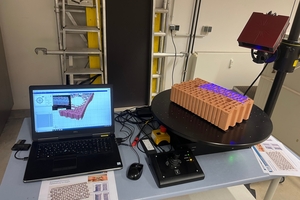

At the second station, two methods for measuring the transverse web thickness sum were demonstrated, manually and with laser and digital recording. At the third station, masonry and the bondings were explained. The participants were then allowed to try their hand at mortarless brick layering. The fourth station was in the MFPA conference room, where Frank Pohle spoke about standards and the determination of compliance with standards.

Lecture block for perforated and dense-fired components

The second block after the lunch break was dedicated to presentations.

Eckhart Rimpel, deputy director of the Institut für Ziegelforschung Essen e.V., reported on research results on the use of masonry rubble as a vegetation substrate for green roofs. Masonry rubble appears to be well suited for this purpose. Due to its significantly lower thermal conductivity, the substrate has a more positive effect on the internal room temperature than conventional substrates.

Dipl.-Ing. Dorte Schaal from CERT Baustoffe GmbH discussed with the participants typical problems and uncertainties that arise in the context of certification and factory production control. The focus lay on clarifying the „second choice“ category.

Dipl.-Ing. Christoph Keller, Managing Director of Güteschutz Ziegel Süd, provided information on the market surveillance procedure, problems that arise and gave tips and solutions for various example cases. He asked the companies to comply with the conditions of the factory test control.

Frank Pohle provided current updates on the product groups of perforated and dense-fired heavy clay building products. Among other things, the presentation dealt with the current status of the Model Building Code, the State Building Code, the Model Administrative Regulation on Technical Building Regulations and the Construction Products Regulation. The current updating of German and European standards was also highlighted.

Dipl.-Ing. Alexander Freyburg, MFPA, discussed clay building products as an unfired alternative for brick manufacturers. Clay earth has greater potential than is generally assumed. In Yemen, for example, there are eight-storey buildings made of clay bricks. In Germany, too, clay building materials are more widespread than expected. Clay bricks form the load-bearing element in around 200,000 buildings from the 18th and 19th centuries. Freyburg then went on to discuss the relevant DIN 18945 standard and made suggestions for earth building practice.

Dipl.-Geologe Holger Kreth, board member of the Keramisch-Technologisches Baustofflaboratorium Hamburg e. V., provided information on current changes to standards for preforated and dense-fired heavy clay building products.

In his lecture, Dr. Dieter Figge drew a static-physical comparison between clay bricks and fired bricks.

Dr. Ralf Wagner (MFPA) discussed the design of functional brick surfaces to influence the urban microclimate and building energy requirements (for details, please see ZI 1/24, page 45).

Guest speaker architect Florian Hoppe, board member of the German Straw Bale Construction Association, talked about load-bearing straw bale construction. There are two different construction methods: Straw bales as infill in post and beam construction, as they exist in France and Germany, and the American way. The latter layers the straw bales on top of each other like bricks. He explained the physical and standardization hurdles and the potential of the construction method.

Evening program

A cultural and gastronomic part of the workshop gave opportunity for relaxation and small talk. The first item on the agenda was a visit to the Museum Neues Weimar (Museum New Weimar). In guided groups, the participants got to know the permanent exhibition. Starting with Friedrich Nietzsche as a pioneering thinker, positions of early modernism in Weimar are presented there.

To end the first day, the organizers invited the participants to a restaurant dinner. .

Practical and lecture block for denser-fired architectural ceramics-

The third program block on the second workshop day consisted of a practical and a lecture part. Similar to the first practical block, there were three stations with different tasks: Determining the size of clinker brick slips and roof tiles as well as forming masonry bonds. Some participants were surprised by the difficulty and scope of measuring roof tiles. At the fourth station, Frank Pohle provided information on German and European standards for dense fired ceramic building materials based on the results of the practical exercises. He discussed key test properties such as bulk density, compressive strength and water absorption.

Dipl.-Geologe Holger Kreth began the lecture part of the second day by providing information on the status of European standards development for brick slips, channel clinkers and roof tiles.

Dr. Dieter Figge, civil engineer, then spoke on two topics. The first was brick slips. Figge presented the DIN 18515-x series and explained the individual standards. In the second lecture, he looked at damage patterns. Using a wide range of examples from building inspections, he outlined typical damage, its causes and gave recommendations for repairing and preventing damage.

At the end of the event, the organizers invited the participants to enjoy a Thuringian sausage in the sunny courtyard of the MFPA.