Sacmi supplies new plant for Creaton/Etex in Poland

This need arose as a result of increases in the surface area of thin extruded products in order to meet the market demand for ever larger tiles, roofing tiles and ventilated façades. Drying of such products on racked cars in traditional tunnel or chamber dryers had become impossible: blowing air onto what was merely the corner of a large piece was nothing less than absurd. Bear in mind that 5% shrinkage over a linear metre corresponds to a huge 50 mm! If such extensive shrinkage were to start from one side only, internal tensions within the material would inevitably lead to cracking.

It was therefore evident that a radical change in the type of machine was required and that products needed to be dried individually with uniform ventilation perpendicular to the product surface. Moreover, uniform shrinkage and the resulting absence of interior tensions allow significant speeding up of the drying cycle.

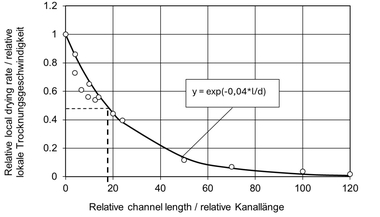

For this reason, Sacmi introduced 3, 4, 5 and 6-layer rapid roller dryers – for extruded tiles, roofing tiles and ventilated façades – onto the market. Each layer (or level) of the dryer constitutes an independent channel where the product is brought into contact with this “technological air” from both above and below by way of blower pipes emitting high-speed air jets. These upward and downward flows can also be adjusted independently.

Dryer design also focused on another key aspect, that of discontinuous operation. The reasons for this are numerous and well known: for example, the need to run the dryer on a 2-shift basis only or interrupt production (press mould cleaning, non-continuous work shifts, etc.).

Dozens of these dryers have been installed for the production of ventilated fa- çades, extruded flooring, step pieces, pressed roof tiles and extruded roofing tiles (»1 to »7)

Roofing tile roller dryer for Polish roofing tile factory

pieces/m2) and 2.4 mill. trims.

For this plant, Sacmi’s Heavy Clay Division has supplied the entire drying department, which consists of:

width: 3.8 m