Goerg & Schneider GmbH u. Co. KG investing in state-of-the-art screening technology

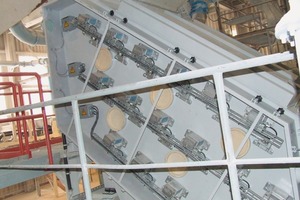

These benefits derive from the function principle of Rhewum’s type-WA slanted screening machine with an inclined screen mesh. Rugged electromagnetic drives mounted outside of the screen housing rock the knocker shafts to make the screen mesh oscillate. The high-frequency motion of the rocker shaft throws the material straight down off of the screen mesh. The gravitational force acting on the milled chamotte can exceed 15 g, or more than 15 times the normal rate of gravitational acceleration. The high acceleration permanently destroys agglomerates, and the separation efficiency improves markedly in the course of milled-chamotte production. Moreover, this principle of function enables a very high throughput rate specific to the screen area.

All during screen operation, the electromagnetic drives can be adjusted by way of an electronic control arrangement, so the vibration intensity can be altered as appropriate for changing material properties, hence significantly improving the consistency of the obtained grain sizes. This adjustability also makes it possible to readjust the targeted grain size in terms of separating boundary. Consequently, a target particle range of 0 to 0.2 mm, for example, can be influenced by as much as ± 5% in its resultant particle-size profile. That way, the separating boundary and/or particle-size profile of the milled chamotte can be better accommodated to each customer’s own needs.

Rhewum’s type-WA screening machines also offer the additional advantage of redundant electromagnetic drives. Even if one of the drives should fail, production can continue on with no loss of quality – and that further advances the well-known reliability and flexibility of milled-chamotte products from Goerg & Schneider.