Aweld exhibits at ceramitec 2024

Since 1996, when the Czech company Aweld s.r.o. was founded, the company has specialised in the production and regeneration of wear parts, such as screws, barrel shells, mixing paddles and many more. Since 2008, Aweld has also been building equipment and machines for the preparation and moulding (extrusion and pressing) of ceramic materials. During its existence, the company has acquired many customers throughout Europe, as well as in Africa and Asia, in a couple of sectors such as the brick industry and technical ceramics. Extrusion presses, twin-shaft mixers, box feeders, rolling mills and, of course, all kinds of wear parts for these plants form an important segment of the company‘s activities today. Aweld is also active in other industrial sectors, such as: Energy technology, waste treatment and biomass processing or technologies for the food industry. The company maintains its broad customer base on a daily basis through its own sales representatives.

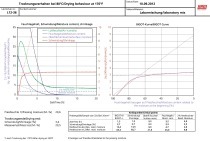

Aweld has a team of graduate engineers and technicians experienced in the industry. The company can carry out both minor and more extensive redesigns of existing technical equipment or supply completely new machines. Aweld achieves very good results thanks to its solutions in the preparation of highly porous ceramic materials and thin-walled bricks pressed from them. However, the company is also strong in technical ceramics in the field of pressing ceramic materials that are difficult to press and are extruded at high pressures of 50 to 80 bar. For these purposes Aweld supplies extruder screw presses of its own design of the AWL series. Aweld has extensive experience in the field of wear protection, where it uses various methods such as: Overlay welding, hard metal spraying of abrasion-resistant materials with PTA plasma or high-speed HVOF spraying or its own wear protection method based on the combination of armouring with tungsten carbide material and Aweld Ceram ceramic platelets. The specific wear protection method is always selected individually for each customer after analysing the requirements and the problem. The solution is then a result in which the costs, technological (rheological) properties and service life are assessed.

Aweld‘s customers can rely on complete customer service, starting with technical advice, through production and ending with assembly and services.

Technical development, high-quality production, quality management system, complete customer service and individualised customer treatment - these are the advantages that Aweld s.r.o. customers benefit from.