Ceratec offers you its heat pump feasibility studies for dryers

Ceratec, a company specialising in process and handling in the heavy clay industry, continues to innovate by offering feasibility studies for the integration of heat pumps in industrial dryers (chamber dryers and tunnel dryers).

By recovering waste heat in dryers, customers can reduce gas consumption, improve energy efficiency and have a positive environmental impact.

Technical and economic feasibility study

Ceratec offers full assistance in carrying out a technical and economic feasibility study. This may include a site visit, unless the site is already known to Ceratec‘s process department. Customers are invited to provide a thermal and aeraulic assessment of their drying installation or to share the information required to carry out this assessment.

Crucial choices

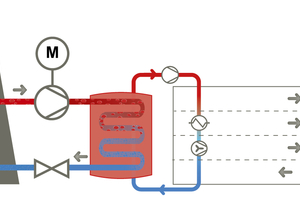

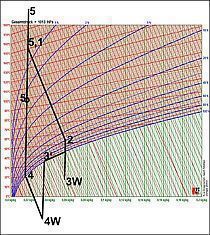

The heat pump is sized according to heat balances, determining the quantities of air and heat required in different zones of a tunnel dryer or drying chambers. Ceratec considers various parameters, including the choice of refrigerant, the number of compression stages, and the method of heat transport.

If required, this study can be integrated into an overall study to optimise the drying and firing process.

As an engineering company, Ceratec considers the specific technical and economical parameters of each project to propose the optimum solution.

Your single point of contact

After an in-depth study, Ceratec issues an offer in collaboration with partners specialising in refrigeration techniques and heat pumps. The preliminary costs for the feasibility study are of course waived if the project is carried out with Ceratec. In fact, Ceratec‘s role in these projects goes beyond that of an engineering office; we also act as an integrator, providing support from A to Z.

Benefits for the customers

Increased energy efficiency

Lower production costs

Lower CO2 emissions

Taking into account country specific incentives

A single point of contact

After-sales service