Craven Fawcett secures major new order with Ibstock plc

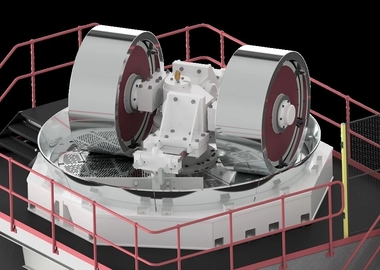

Craven Fawcett, one of Europe’s leading manufacturers of clay preparation and extrusion machinery and part of Group Rhodes, has won a major new contract to supply the first net zero carbon emissions brick facility in the UK.

The multi million pound project will see Craven Fawcett design, build, and manufacture a fully integrated state-of-the-art clay preparation and extrusion line at Ibstock’s Atlas site in the West Midlands. The news follows Ibstock plc’s announcement of £60m investment in its Atlas and Aldridge plants, which will collectively deliver an additional 115 million brick capacity per annum.

Andrew Craddock, Engineering and Manufacturing Development Director at Ibstock Brick, said: “As a supplier to Ibstock for many years, we are aware of the capabilities of Craven Fawcett in designing and building new production lines to meet our exacting requirements. This is an important undertaking and we are pleased to be working with a UK partner that not only has the expertise in clay preparation and extrusion technology, but also understands Ibstock’s holistic approach to its corporate business sustainability strategy”

Mark Ridgway OBE DL, CEO of Group Rhodes, said: “We are delighted to be working with Ibstock on this exciting project which has great product design and UK manufacturing at its heart. As a business, we are committed to good environmental practices and are pleased to be able to support projects where improved sustainability is a critical outcome. Goods will be sourced with low environmental impact, and we will be working with local suppliers wherever possible”.

As well as being a major capital project win for the company, Craven Fawcett is geographically well placed to supply Ibstock’s new facility in the West Midlands with the necessary aftermarket support. Craven Fawcett also finances consignment stocks throughout the UK and overseas to ensure customers have quick access to critical spare parts when required.

Glynn Dixon, Contracts Manager at Craven Fawcett, explains: “Ibstock has been a highly valued customer of Craven Fawcett for almost 40 years. We are naturally very pleased with this major new contract win and are looking forward to designing and building this bespoke cut clay brick line to further enhance Ibstock’s strong market position.”

Over the coming months, Craven Fawcett will be recruiting additional design and engineering staff to service this and other recent contract wins. It is also expected that Craven Fawcett’s sister company, Hallamshire Engineering Services will be supplying conveyor drums and rollers to the project. The Ibstock contract is expected to take approximately 24 months through to final commissioning.

Craven Fawcett has supplied extruders and other machinery to the brick and clay pipe manufacturing industry for over 175 years and is at the forefront of technology in the field of clay preparation and extrusion. The company manufactures a range of special equipment including Box Feeders, Grinding Mills, Roller Mills, Mixers and Extruders. The equipment is sold globally into the heavy clay and ceramics industry, and also into the mining, quarrying and environmental sectors.

Alongside high-quality Original Equipment Manufacturer (OEM) products and services, Craven Fawcett offers guidance on material selection, component finish and supply of spare parts in order to optimise production efficiency and reduce the frequency of machinery repair. This is backed by a team of highly trained and experienced service engineers dedicated to clay preparation and extrusion machinery, who can repair and maintain Craven Fawcett equipment both on and off site.

Ibstock plc history spans over 200 years and is a leading UK manufacturer of clay bricks and a diversified range of clay and concrete products. The Group‘s clay division is the leading manufacturer by volume of clay bricks sold in the United Kingdom. With 16 manufacturing sites Ibstock Brick has the largest brick production capacity in the United Kingdom. It operates a network of 18 active quarries located close to its manufacturing plants.