Craven Fawcett supplies new machinery to Nigeria

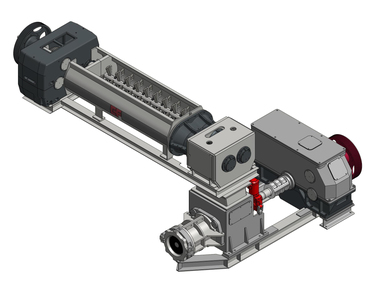

The British firm Craven Fawcett Limited, based in Wakefield, West Yorkshire, has recently supplied a Nigerian Company with a new Centrim 410 extruder and rotary plastic feeder as part of a clay preparation line.

The Centrim 410 combination 16-inch diameter extruder and double-shafted mixer/pug sealer is ideal for processing the difficult Nigerian clays, and will produce up to 14 000 perforated bricks or hollow blocks per hour. Encompassing a large de-airing chamber with twin packers to reduce bridging, the extruder includes wear resistant augers of 28% chrome alloy and chrome mixer blades of variable pitch.

The selection of a Craven Fawcett extruder was based on the machine’s excellent reputation for stiff extrusion of abrasive materials. The Centrim 410 is fitted with a split and hinged barrel design for ease of maintenance, and a double-hinged mouthpiece to cater for frequent die changes. To ensure that the Nigerian customer received a complete turnkey package, Craven Fawcett’s associate company, Tecnofiliere S.r.l, based in Italy, supplied the hollow block dies for the extruder.

The rotary plastic feeder has a nine tonne storage capacity and provides an even feed of prepared clay from double discharge doors.

As one of a few companies in the world capable of manufacturing a full range of quality clayworking machinery, the Craven Fawcett production facility offers excellent design, fabrication, machining and fitting departments. All aspects of machine build are controlled to the Company’s high quality (ISO 9001) and safety standards.