New cooling element with great potential for the brick and tile industry

The threat of climate change triggered by the rising concentration of CO2 in the atmosphere can only be stopped with measures to reduce CO2 emissions. Solutions that have been found for the automotive industry could prove helpful here. There, the question of how much CO2 is produced during the manufacture of a car is irrelevant. On the contrary, as a result of the automation of production processes, energy requirements and therefore CO2 emissions have increased. The decisive criterion for national legislators was the reduction of CO2 during the use of the vehicle, as this consumes a multiple of the amount of energy required for the manufacture of the product. Once the transitional periods have expired, road transport should no longer produce any CO2.

This approach could also be adopted by the brick and tile industry, if products are manufactured there that can help to ensure that no CO2 is produced when heating and cooling rooms. This technology exists as an air conditioning element and has proven its worth in the 8 years it has been in operation.

1. Energy source

Air conditioning a room with a water-bearing system is preferable to any air-bearing system. This is because one litre of water can transport 3000 times as much energy as one litre of air. In addition, operating an air conditioning system (ACA) requires loud, power-consuming fans and large pipe cross-sections. When water is used as the energy source, small pumps ensure a pleasant indoor climate. If the energy is emitted via large surfaces (wall or ceiling) instead of small, water-bearing radiators, a lower flow temperature is required for heating.

2. Air temperature and radiant energy

The radiation emitted by the surfaces enclosing the room is more important for the well-being of the occupants than the air temperature. In a room with an air temperature of 25 degrees, you don’t feel comfortable if the walls are only 14 degrees. However, at an air temperature of 14 degrees, you feel comfortable if the walls emit their energy by radiation at a temperature of 25 degrees. Sunbathing in the high mountains is possible at very low air temperatures even in winter.

3. Heating is no problem, but cooling is!

When heating, there are no building physics problems on the room-side wall surfaces. The situation is different with massive cooling. If warm air meets a cool surface, condensation forms. In winter, everyone can observe this phenomenon for themselves, for example on the bathroom window before and after showering.

In order to be able to cool massively, the surface intended for heating and cooling must therefore be able to absorb moisture, store it, transport it to dry wall layers and ideally even release it to the outside air. This is only possible if the wall structure is open for moisture transport and not hindered by vapour barriers. The climate element fully fulfils these capabilities when it is fixed to a wall made of fired backing bricks. Their capillarity ensures that the condensate can be easily removed to the outside.

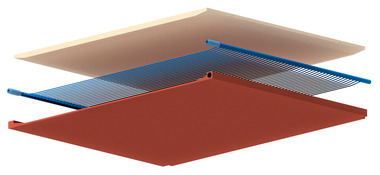

4. Production of the climate element

The climate element consists of three layers: a 5 cm thick calcium silicate panel measuring 122.5 cm x 60 cm (other formats are possible), a capillary tube mat and a clay plaster to fix the mat in prefabricated grooves. The air conditioning elements are manufactured in a production facility measuring approx. 3 x 15 metres. After production, the air conditioning elements should dry for 24 hours.

Production takes place in three steps. Firstly, a wedge is sawn off at both ends of the calcium silicate panel to allow the 2 cm thick supply and return of the capillary tube mats to be laid deeper. Grooves approx. 5 mm deep are then milled in which the inserted mat is fixed with an adhesive made from clay powder.

Fixing to the wall or ceiling is done with an adhesive made from clay powder and, if necessary, with screws, especially on ceilings. After completion of the supply and return lines and a 2-day check of the tightness of all welded seams, the joints are filled and a surface plaster, which has been tried and tested with a plaster mesh, is applied. Lime is added to the clay plaster to prevent mould infestation of the clay plaster, which is soaked with moisture due to condensation absorption.

5. Production of the climate elements

For various reasons, it is advisable to entrust brickworks with the production of the regionally required climate elements. Firstly, they have the clay deposits required for the production of the climate elements. Secondly, brickworks have long-standing good contacts with the local architects and craftsmen in their region, so that the instruction/training of customers for correct installation can be ensured without any problems. Thirdly, this sales concept should prove advantageous for brickmakers. For reasons of building physics, buyers of climate control elements will also opt for clay blocks when planning load-bearing walls.

6. Sales-increasing co-operations

In order to cover the energy requirements for heating and cooling, heat exchangers must be installed to convert the electrical energy generated by solar technology. It will therefore be advantageous in many ways if the manufacturers of the climate control elements work closely with the local suppliers of heat exchangers and photovoltaic panels/foils and, above all, jointly ensure the training of architects and craftsmen.

7. Costs of the innovative technology

Whether the new technology described above can be installed at the same price as an ACA can be predicted for all regions of the world. In many countries, innovative technology for CO2 neutral room air conditioning is being subsidised. In addition, unlike with an ACA, there are no operating costs when using air conditioning elements. Comparative calculations have shown that - even without state subsidies - the higher investment costs are likely to be amortised after four or six years at the latest.

8. Corporate structure

Due to the worldwide demand for CO2 neutral air conditioning technology, only a franchise structure can guarantee a rapid market launch and optimum co-operation between the franchisor (Ecoclimate GmbH) and the franchisee (brickworks, architects, etc.). This form of co-operation offers advantages to both business partners: should any franchise partner experience problems with production or distribution, Ecoclimate should be informed immediately.

The franchise partners should also report on all state and other subsidies that are available in their region for the franchisee, but also for the building owner. Ecoclimate will regularly inform all franchisees about possibilities for eliminating technical problems, but also about new state subsidy programmes.

9. Current homepage

Further information can be found at www.ecoclimate.info, including an article on the practical use of the climate element at the University of the Balearic Islands: Dr Andre Moia Pol (University of Palma, Mallorca): Net zero emissions for a seminar room in the University of Balearic Islands. If the information provided there is not sufficient, we are happy to receive any enquiry.