University at Buffalo preps for largest-ever U.S. earthquake test of brick-and-mortar building

Unreinforced masonry (URM) buildings are everywhere. Residences, stores, restaurants, schools, fire departments and other critical infrastructure are commonly housed in URM buildings. These buildings are well known for their seismic vulnerability.

A new University at Buffalo (UB) project could make these critical structures more earthquake-resistant while also creating educational opportunities for young adults.

“URMs have a unique appearance, but besides aesthetics they are good in terms of energy efficiency, durability, and they do well in case of fire and wind/storm,” says Andreas Stavridis, associate professor of structural engineering and deputy director of the Structural and Earthquake Engineering Simulation Laboratory (SEESL). “However, they do not perform well during earthquakes. In every city I have visited following a devastating earthquake in Europe, Asia and Latin America, URM buildings are the most damaged ones.”

Stavridis, principal investigator on this National Institute of Standards and Technology (NIST)-funded project, is collaborating with co-principal investigators Kallol Sett and Michel Bruneau, both structural engineering faculty members. The researchers’ goal, according to Stavridis, is to improve the resilience of existing URM buildings.

“We want to improve the performance of existing URM buildings during extreme loading events, like earthquakes. We also want to improve their resilience; that is, ensure they are able to recover and function after such events in a reasonable amount of time with minimal interventions and costs,” Stavridis says.

This type of construction was banned in California after damage suffered during the 1933 Long Beach earthquake, but many URM buildings remain in California and in significant portions of other U.S. cities. In addition to housing critical community infrastructure, many of these buildings have historical significance. The research group will develop a framework for the design of reliable and cost-effective retrofit methodologies suitable for these structures.

Researchers anticipate findings from this project will directly influence the American Society of Civil Engineers (ASCE) standard 41, which is titled the Seismic Evaluation and Retrofit of Existing Buildings. This standard uses different performance-based methodologies to evaluate and improve, or retrofit, the performance of existing buildings during earthquakes. The research team at UB has experience contributing to ASCE codes and standards, and works with a nationwide panel of professional engineers with significant experience on URMs.

“Our main line of work is assessment and retrofit — diagnosing materials and construction typology of existing buildings and designing repairs and strengthening measures,” says Michael Schuller, structural engineer and president of Atkinson-Noland & Associates Inc. (ANA), one of the industry advisory group members. “We have worked on masonry construction throughout the United States and around the world since 1975.”

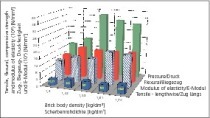

As a member of the project’s advisory group, Schuller and ANA help define common issues associated with the performance of URM buildings during earthquakes and provide advice on the types of brick and mortar, and other types of construction materials, found in earthquake-prone areas. According to Schuller, this work will improve knowledge and develop better ways to analyze and predict earthquake responses.

“Ultimately, this will lead to life safety and cost improvements for building occupants and owners,” Schuller says.

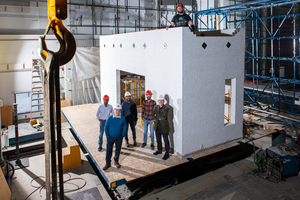

Largest structure of its kind ever tested in U.S.

Before researchers make recommendations to any codes or standards, though, they have to test a full-scale specimen. Over the past three years, a team of graduate students, and students and instructors from the U.S. Department of Labor program Job Corps have built and tested several URM walls. The team used the results of these tests to design the current brick and mortar URM structure. Greg Congdon (BS ’15, MS ’17), is one of three PhD students working on the project, and the current phase of his research focuses on the full-scale testing on the shake table. According to Congdon, the impact of this test and his research could extend far beyond these results.

“This is the largest structure of its kind ever tested on a shake table in the U.S.,” Congdon says. “I will use the outcomes of this test to evaluate current engineering practice and inform the development of my mathematical models. I want to use these models to extend my study beyond the test structure to more than a couple types and layouts of URM buildings.”

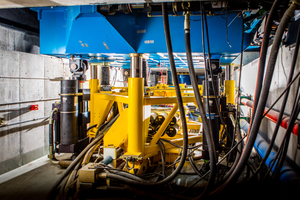

UB’s SEESL in Ketter Hall is one of the few spaces in the country capable of carrying out a test like this, according to Stavridis.

“It is quite complex and expensive to test structures of this size. We do not have many opportunities to test such structures, so it took us a while to get ready. Very few labs in the U.S. can handle such a test,” Stavridis says. “Researchers tend to focus on improving new construction guidelines and we tend to neglect existing buildings. Old buildings are more challenging.”

Construction on the test specimen began in January. To assist with the project, Stavridis reached out to Job Corps, the largest free residential education and job training program for young adults ages 16–24. According to Robert Kelichner, bricklaying trade instructor at the Iroquois Job Corps Center in Medina who is assisting on the project, the program provides students with in-demand skills.

“Iroquois Job Corps has a college-like atmosphere where students have the opportunity to receive their high school diploma, GED or work directly in the trades and other programs offered at the center,” Kelichner says. “A lot of young adults come from not-so-great backgrounds, where Job Corps is an escape and a place where they can focus on a program. Completing the program sets them up for a better and more prosperous future.”

SEESL developed a partnership with Job Corps allowing students in the program to gain real-world experience building the test structures. The students work with professional engineers, graduate students and other researchers, and for this project specifically, apprentices in the bricklayers local 3 union in Buffalo; the arrangement helps the lab build structures faster. Job Corps students learn skills necessary to be successful in the construction industry and learn more about higher education.

“It takes some time to understand what this trade truly is,” Kelichner says. “This shows them how masonry can change over the next 10-15 years, as everything is constantly in motion. I see a curiosity and willingness to learn among our students. They may become role models to those they interact with daily, or to any younger siblings who may look up to them.”

These students also receive a glimpse into structural engineering research. While on campus, Stavridis gave them presentations on past research projects and discussed the challenges engineers face when working on older buildings.

Gaining new insights

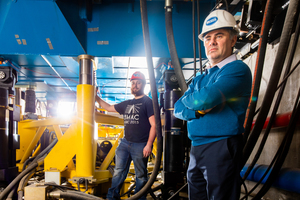

Testing began March 13, and according to Stavridis, these findings will fill a fairly substantial void.

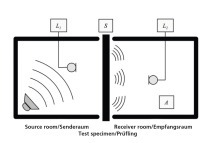

“Our goal is to assess current strengthening methods. It will be the first time these methodologies are being tested on a building shake table under three dimensional dynamic loads,” Stavridis says. “We have very little data, if any, from such tests in the U.S. We will have over 160 sensors on the structure to learn as much as we can about its behavior. During the tests we may pause and repair the structure to assess costs and effectiveness of repair strategies as well. If needed, we will test a second structure next year to propose and evaluate alternatives.”

Stavridis is a member of the ASCE 41 standard masonry committee, and the current and former chairs of the committee are members of this project’s industry advisory panel. Once tests are complete, and the data is analyzed, the team’s familiarity and roles on these different committees could provide a path for direct implementation. If the findings support new ways to enhance URM buildings and their resilience to earthquakes, the impact could be significant, according to Stavridis.

“This can provide a measure of the safety for the structures already retrofitted, but also improve the guidelines and engineering practice for future retrofits,” Stavridis says.

To follow along with project updates, visit the project‘s website.