Cross-dredging souring plants by Händle are all the trend

In the past, most cross-dredging souring plants could be found at roof-tile production facilities, where the idea was to improve the mixing effect of longitudinal-dredging souring plants. One of the first cross-dredging souring plants ever built was built by Ludowici in Jockgrim in 1928. Since then, Händle has played a major role in the further development and introduction of souring plants in the brick and tile industry and has planned, built and delivered a great number of souring plants to all corners of the world.

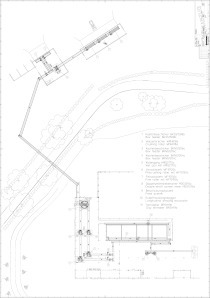

In a cross-dredging souring plant, the best mixing effect is achieved by depositing the clay horizontally, in layers as thin as possible across a large area, and then retrieving it vertically with a cross-dredging bucket-chain excavator that cuts through all layers in a single sweep. In order to optimize the mixing and homogenizing effect, different material-store filling patterns have been developed for implementation via the program-controlled filling system. In addition to serving as a blending-bed system for raw-material homogenization, the typical cross-dredging souring plant also has the following functions: tempering, body moisture equalization, shielding of production from climatic effects, and buffering between preparation and shaping.

Now, cross-dredging souring plants are used not only by roof-tile producers, but in practically all parts of the brick and tile industry and in branches beyond the ceramic sector.

The Händle cross-dredging souring plant programme comprises five models defined by their respective bucket size: 30, 45, 60, 75 and 100 litres. The corresponding dredging capacities range between 45 and 130 m3/h bulk material. All cross-dredging excavators can be sized for basin depths between 6 and 11 m, and the associated excavator traverser fits basin widths of 10 to 30 m. Any arbitrary storage capacity can be implemented.