The excavators that Händle engineered in cooperation with Petersen, DK-Broager, are now being manufactured by Händle (

www.haendle.com ) alone. In that connection, the entire line of practice-proven excavators has been optimized in all detail to reflect the latest state of the art. Already, Händle has logged a number of orders. So far in 2010, four longitudinal excavators have been delivered, including two with 45-litre buckets for Russia and one with 50-litre buckets for Trinidad. One cross-dredging excavator with traverser and 150-litre buckets, designed for a basin depth of 8 m and a basin width of 22.5 m, will soon be dispatched to Indonesia.

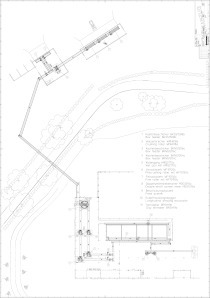

Händle’s souring plant excavator programme comprises one series each of longitudinal excavators, type EKBL, and cross-dredging excavators, type EKBQ. Both series can be equipped with 30-, 45-, 60- and 75-litre buckets for corresponding discharge capacities of 40, 60, 80 and 100 m3/h. Special bucket sizes can be implemented, too: buckets holding up to 200 l are on record. The longitudinal excavators come with bucket-ladder lengths ranging from 7m to 18 m and a maximum swivel range of 90° (+45° to –45°). An inclination sensor now tracks the position of the bucket ladders. The cross-dredging excavators with traverser are designed for basin widths of 12 m to 30 m and basin depths of 6 m to 10 m.

A few of the many design details:

› �Both, the driven tumbler and the idler (turnaround) tumbler, are equipped with identical three-piece ring gears enabling segmental replacement without need of dismantling the excavator chain

› �An uneven number of teeth on the tumblers guarantees optimal chain engagement and prevents uneven wear

› �Hydraulic raising and lowering of buckets is implemented by means of two double-acting cylinders with two-stage lifting speed control

› �The chain is automatically tensioned at the idler (turnaround) tumbler by a hydraulic tensioning cylinder

› �The chain is automatically lubricated

› �The easily replaceable buckets with cutting knives and side cutters are made of heavy-duty special steel

› �With the aid of a hydraulic cylinder, the material scrapers can take up either of two positions, depending on the bucket capacity, to optimize bucket evacuation

Händle supplies not only the excavators themselves, but also the transport system required for filling and emptying. Special attention is paid to the defined deposition of raw material in special, predetermined patterns to achieve the best possible mixing and homogenizing effects with the help of a programmable logic control (PLC) system and corresponding software.

Thanks to sophisticated, programme-controlled material deposition techniques, many old souring plants have now been turned into up-to-date blending-bed systems.

Händle GmbH Maschinen und Anlagenbau

Industriestraße 47 I 75417 Mühlacker I Germany

T +49 (0) 70 41 89 11 I F +49 (0) 70 41 89 12 32

info@haendle.com I www.haendle.com