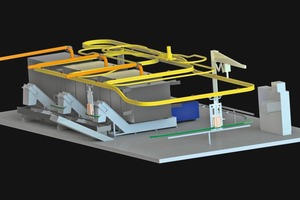

Automatic plaster purging plant ARA:

cleans plaster moulds quickly with low labour outlay

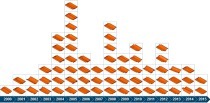

Franz Banke GmbH has installed a pair of automatic plaster purging plants at Röben’s two roof tile factories in Sroda Slaska. All objectives in terms of capacity, savings potential, reliability and efficient cleaning of moulds were fully achieved. The automatic mould purging system ARA2 at the first roof tile factory was commissioned in 2009 and has been in productive service ever since with no considerable unscheduled outages. The ARA3 plant at the other factory was installed two years later and has also been running smoothly from the first day on.

1 Introduction

In Central and Northern Europe, most high-quality clay roof tiles are made in plaster moulds. That way, clearly defined ribs and structures can be pressed into the tiles to give the roof the best possible water- and wind-repelling qualities. Plaster is also the moulding material of choice for flawless finishes and high frost resistance.

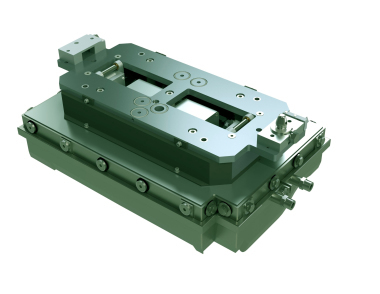

Plaster working moulds are shaped by casting or pressing. More than 1 000 tiles can be pressed with a single plaster liner. The actual end quantity, i.e., the service life of the plaster mould, is crucially dependent on the employed materials...