Franz Banke GmbH to showcase mould-making and wear prevention

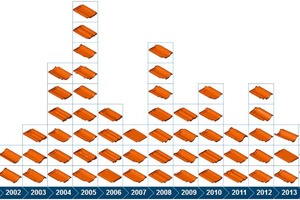

At this year‘s ceramitec, Franz Banke GmbH will be looking back on 15 years of roofing -tile development and presenting notable innovations in mould-making and wear prevention.

Franz Banke GmbH has been a partner to the clay roofing tile industry since 1978. In its first two decades, the company became known as a reliable supplier of pure hardware items like wear parts, working moulds and suction heads. Then, in the year 2000, the first set of moulds to have been completely engineered by Banke in close cooperation with the customers went into service.

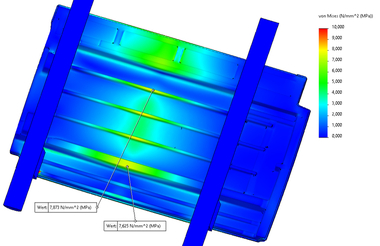

Ever since then, Banke has been fine-tuning and refining its heavy clay engineering options. New processes, including the use of finite-element analysis, have been adopted along the way. In the meantime, more than 60 new roofing tile models have been developed to market maturity with the help of Franz Banke GmbH. In addition, numerous individual tiles and tile families have been reengineered and optimized by means of an optical digitizer, three-dimensional CAD engineering tools plus lots of experience and know-how on the part of Banke‘s staff.

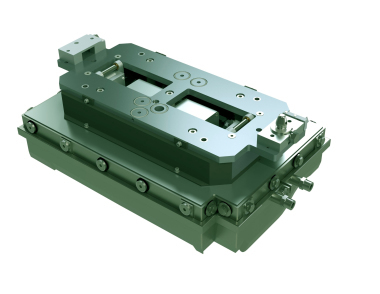

A number of roofing tile models that Banke has developed all the way to market maturity in recent years in close cooperation with and for the customers will be on display at the Banke stand.

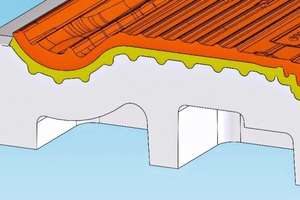

Pressing clay roofing tiles with thinner plaster liners and improved endurance for wear parts

For some time now, Franz Banke GmbH has been working on a pair of potential means of cutting costs in the shaping process. Instead of the usual 16-18 mm-thick plaster liners, a thinner version can be used, thereby reducing overall plaster consumption. Also, a number of wear-prevention coatings have been successfully tested for wear parts like border stripes and knives. All this will be on display.

In addition to these innovations, the Franz Banke team will be presenting the company‘s full remaining range of products and services, from the engineering of new roofing tile models and detail design options for mould sets to such plaster preparation systems as the AVM20 vacuum plaster mixer and the ARA automatic plaster spraying system.

Hall B2, Stand 200