Franz Banke GmbH celebrates 35th anniversary with customers and business partners

Founded in Isen in 1978, Franz Banke GmbH has become firmly established not only on the German but also on the European market with its mould and accessories manufacture for the clay roofing tile industry, which makes up around a third of the company’s sales today. The customers come, for instance, from Poland, Portugal, France, Croatia and Serbia, but the company has already worked on projects in Malaysia and Thailand too. In all the years, Franz Banke GmbH has developed new areas of business and markets and constantly adapted its machine equipment to meet rising challenges. With the new building completed at the end of 2012, the company wants to push ahead with its apprenticeship scheme. Ample reasons for the company to celebrate its 35th anniversary together with customers, business partners and the entire workforce on 20 September at a company exhibition and give its guests a look behind the scenes.

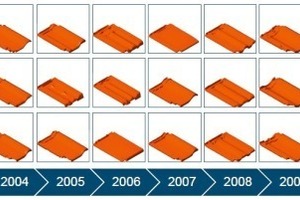

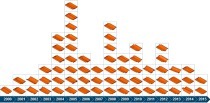

Thomas Banke, Managing Director at Franz Banke GmbH, was able to welcome almost 85 visitors from Germany, Croatia, the Netherlands, Serbia and Poland and relate to them the company’s success story. Franz Banke, Senior Partner today, started small with huge support of his wife like many other successful companies: he founded his company in a garage. Bit by bit, the mould making part of the business was extended and investments made in a company site and production facilities. The constant expansions included in-house model making and the production of master moulds. Up to the year 2000, the Isen-based company was purely a mould maker. With the development of new roofing tile models, the company opened up a new area of business. The first complete roofing tile model including accessories developed by the company was another milestone in its development, many more followed, as »6 shows. In 2011 work began on the construction of a new production facility in which the training workshop was also integrated. Training is a very important topic at Banke, one of the largest employers in the region, and an investment in the company’s future, 10 of 50 employees are apprentices. The efficient transfer of know-how in the company is shown by the successful handover of the management by Franz Banke to his son Thomas in the year 2009. Today the Senior Partner and his wife support their successor in administrative work and help him with their many years of experience. Franz Banke emphasizes that working with the customers was always a pleasure for him. Goal of the likeable Senior Partner was their satisfaction. He thanked his customers and business partners for the many years of good cooperation and support. Thomas Banke, who with his 35 years is as old as the company, became involved in his parents’ business early on. Following his apprenticeship as a fitter and studies in mechanical engineering and prior to taking over management, he worked as chief designer. Under his direction, the company developed the business lines of “roofing tile development and optimization”. Today Banke works closely together with customers to develop around three complete models with all accessories every year and also reworks individual roofing tiles. These include award-winning models like the Achat 12V from Monier- Braas. Roofing tile mould making and development makes up about 95% of sales, the rest comes from contract manufacturing.

The company is especially proud of its own development of a plaster spraying system. The idea came around 15 years ago, it was realized in close cooperation with the Managing Director for Engineering Matthias Grziwa from the Polish Röben plant ´S roda ´S la˛ ska. The first system was commissioned in Plant 2 in 2009. In his user talk, “Field report on the Ara 2/3 automatic spraying system”, Matthias Grziwa spoke about the success story. Basis for the fruitful cooperation were for him the extensive technical know-how at Banke and the will and financial means for the investment by Röben. Röben‘s Polish roofing tile factory produces 76 mill. flat tiles and 6 mill. accessories, in three shifts on 365 days a year. Goal was to automate the plaster spraying of worn plaster moulds, leading to a reduction in the high labour requirement necessary for the manual set-up of the conventional manual spraying system and the manual removal of the plaster inserts from the working moulds. With the investment, an automatic feed of the moulds, their efficient and gentle cleaning was to be achieved with lower labour requirement and costs while performance was to be enhanced. Grziwa expressed his satisfaction with the performance of the system that operates trouble-free. Following the successful implementation of the first system in Plant 2, in 2010 Röben invested in a second, modified spraying system in Plant 3. This too operates extremely reliably.

The in-house exhibition at Banke provided various business partners with the opportunity to present their products and services, these included Rotho, Stafier, Keller HCW, Lingl, Händle, Casea, Saint-Gobain Formula, IKF and HK Ceram.

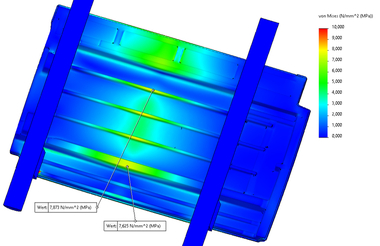

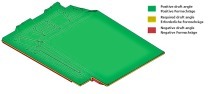

Everyone, customers and partners, seemed very impressed by the capacity and the extensive and very modern machinery at Banke. On a large number of CNC-controlled machining centres, parts made of steel, aluminium and plastic up to a size of 4 x 1 x 0.85 m are machined. With regular investments in new equipment, the company remains at the state of the art and opens up the possibility for increasingly streamlined production. One reason for the success is certainly that Banke supplies almost everything from one source. This guarantees short supply times, high-quality products at competitive prices and ultimately satisfied customers. All essential development and production steps are networked and integrated under one roof. The company endeavours to perform as many production steps as possible in-house, from design through engineering of the tools to production and final assembly.

With the company exhibition and anniversary celebrations, Franz Banke GmbH presented itself to its customers and partners as a modern and forward-looking partner for the clay brick and tile industry.

⇥Anett Fischer