Bedeschi supplies BFS Tunisia

For this new brick plant with a production capacity of 1600 t/day, Bedeschi was contracted to supply the complete preparation line including clay storage and extruder. The scope of supply comprises:

two large CNL 8/1500 apron feeders for the two types of clay

one CNG 4/1200 apron feeder with rubber belt to shorten the clay mix with the addition of sand and

one large RS 650/1500 crusher

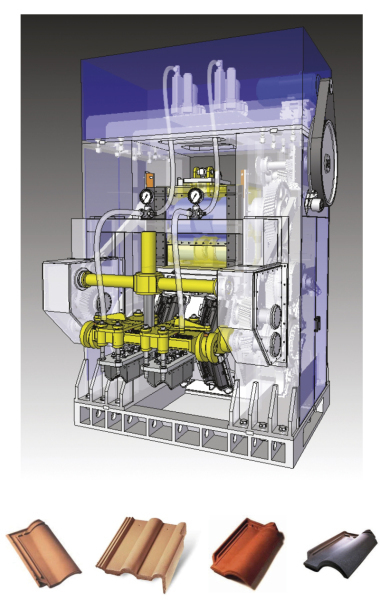

On consultation with the customer, the processing of wet material was enabled with the installation of a DS 650/1500 disintegrator downstream of the crusher and two parallel switched LPS 12x10 roller mills. If the customer wants to process dry material, downstream of the disintegrator the line is equipped with a mobile conveyor belt that transports the material to a series of hoppers to feed four large impact crushers. Of these two work while two others remain in stand-by operation.

The line continues with two 8/1500 apron feeders with high filling capacity, which batch the clay for the GGS 5000 double-shaft mixer. This mixer in turn feeds the clay silos, which are equipped with one BEL F 130/14 lateral bucket reclaimer, one of the latest generation of this type of reclaimer. Downstream of the clay silos, preparation is continued on two identical lines, consisting of two CNL 6/1500 apron feeders, two LPS 12x2 roller mills (an optimized and highly efficient machine), two GG 4500 filter mixers and two BED 750 SLS extruders. Belt conveyors and electric switch boards complete the installation. The project is still under construction and should be commissioned soon.

Bedeschi SpA

www.bedeschi.com