Biomass for sustainable brick production

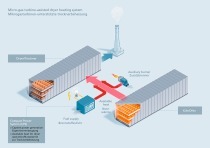

In the project, a wood gasifier provides the process heat (500 to 1000 °C). The carbonaceous residues from the gasifier are used as pore-forming material in the brick. This cascade utilization reduces the disposal costs, improves the product properties of the brick, saves fossil fuels and increases the cost efficiency of the process. The project consortium consists of plant manufacturers and users. Fraunhofer UMSICHT is responsible for project coordination and accompanying research.

Under what general conditions would the operator of a brick plant switch to renewable energies? This question occupied the researchers at Fraunhofer UMSICHT and was the motivation for the “BioBrick” project. The background of the project is to promote the use of biomass in industry, especially in the area of process heat supply, in order to displace fossil fuels and save on CO2 emissions. The project has two main focuses:

Focus 1: Energy supply via biomass

In the first focus area, a concept is being developed with the plant manufacturer and the brick plant for the integration of wood gasification technology and a combined heat and power plant into the site’s energy supply. At present, the tunnel kiln for the production of bricks is heated with natural gas. In order to reduce the demand for natural gas, a wood gasifier is integrated to produce synthesis gas.

In the first scenario, this is used to operate a CHP unit, the waste heat of which will be used to heat buildings on the site and generate electricity for production. As an innovative option, it is being investigated whether the hot exhaust gas stream from the CHP unit (upstream of the heat exchanger) can be used directly as process heat for heating the tunnel kiln.

In the second scenario, the synthesis gas from the wood gasifier is used directly for production via modified gas burners.

Focus 2: Material use of gasifier residues

The second focus of the joint project is the material use of the gasifier residues as pore-forming material in bricks. The focus is on the development of advantageous recipes and the question of how the gasifier residues can be optimally introduced into the brick and distributed therein.

The different possibilities are tested and evaluated according to test procedures. In the case of bricks, the focus is on strength, dimensional stability and thermal insulation properties. Variations in ash content, ash composition and carbon content of the initial substrate are investigated.

After the preliminary tests in the pilot plant, the gasifier coke is delivered to the brick plant and introduced into the production process in defined test batches. The quality of the finished bricks is tested by an independent external laboratory.

Project consortium

Fraunhofer UMSICHT at the Sulzbach-Rosenberg site is responsible for the coordination of the project as well as the conception of the energy supply and integration into the site. The company Burkhardt GmbH and the brickworks Ernst GmbH & Co. KG are mainly investigating the material integration of the gasifier residues.

Sulzbach-Rosenberg Branch

Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT

www.umsicht-suro.fraunhofer.de