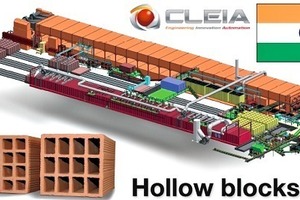

With the contract for the extensive revamping of a brickworks awarded by Arth Ceramics (formerly Red Ceramics Ltd.), Cleia, the French plant engineering company, is continuing its international development. The modernization of the plant in Kolkata, West Bengal, will increase the annual output to 200 000 t hollow blocks, making it one of the largest brick plants in India.

For Arth Ceramics, the clinching argument was not only that Cleia supplies innovative solutions for existing units together with a strong commitment to ensuring reliable operation. The heavy clay testing conducted by Cleia for over a year was a key factor in the decision of Arth Ceramics to select Cleia as its partner for the complete realization of this project.

Hollow blocks are a major development for the construction industry in India: in comparison with solid bricks, they reduce construction costs as well as the energy consumption and raw material quantity needed.

New perspectives for the raw materials process in India

Cleia ceramic engineers with their extensive 4C laboratory – Cleia Ceramic Competence Center – will develop new technologies for the raw materials preparation process adapted to the local conditions in India.

Modern and fully automatic equipment

Cleia will install a new Sirocco rapid dryer perfectly adapted for drying hollow products. The existing kiln will be renewed and fitted with new firing and control equipment. The handling facilities will be replaced with robotic setting stations. All the equipment will be controlled with an OpenCer PLC control system.