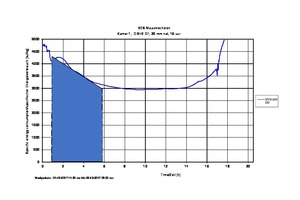

Findings from the new hybrid dryer project

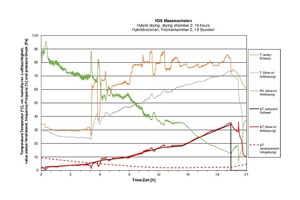

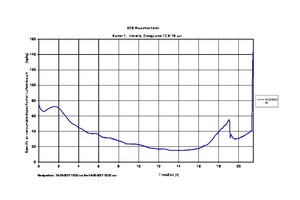

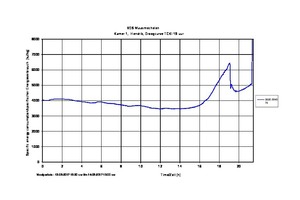

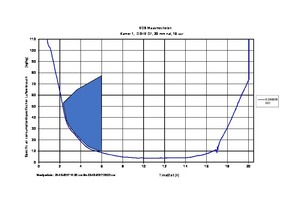

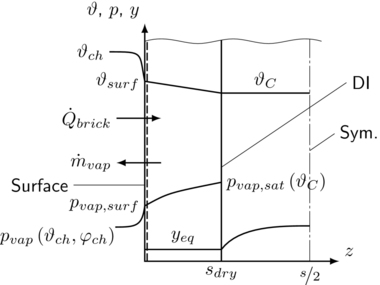

For the ceramic industry, reducing CO2 emissions and achieving the necessary savings on energy will require extensive effort and significant investment volumes. A new type of dryer developed at TCKI, as presented below, was tested out in a demonstration project. The results showed that, in production plants with low kiln waste heat, semi-steam drying can be introduced in one or several drying chambers. The use of hybrid drying is strongly dependent on cost-benefit behaviour.

1 Introduction

In 2010 and 2011, as part of the “Road map 2030 for the ceramic industry in the Netherlands“, TCKI investigated technologies and techniques for minimizing energy consumption and CO2 emissions in the production of bricks, roof tiles, stoneware pipes and tiles – defined as the “Factory of the future“. Implementing the “road map“ necessitated the development of a new drying system for structural clay products.

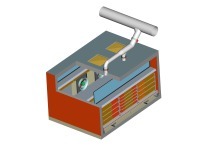

TCKI, the Dutch Centre for Ceramic Building Materials Industry, took the initiative and introduced a new type of chamber dryer. This hybrid drying system enables lower energy...