HUP-Pietz Verschleißschutz GmbH expands production

A pair of modern CNC underwater plasma cutting systems, plus presses, a sheet metal bender, boring machines and MAG welding equipment enable HUP-Pietz to cut, shape, drill and weld “Trinox quality” wear plates (up to 600 HN). HUP-Pietz provides on-the-ground technical consulting services and optimized constructional implementation with state-of-the-art CAD software, including drafting.

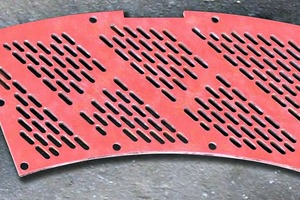

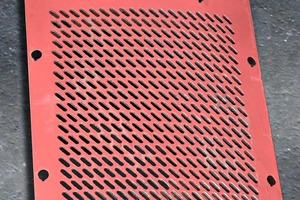

Now, in addition to their dependable regenerating work, HUP-Pietz can produce and hardface new parts and components for the ceramic industry. In addition, the production programme now includes pan mill plating, screen plates, scraper bars and wear applications made of Hardox, compound wear plates or steel plates in thicknesses up to 50 mm.