Heat recovery from flue gases by means of polymer-based heat exchangers

The challenge

The production of clay bricks and roofing tiles is an energy-intensive process, in particular the firing and drying process steps. Even if partial heat integration has already been implemented, a significant amount of energy is still lost through the stack, where flue gas is emitted at elevated temperatures. Recovery of this heat using traditional heat exchangers has always been problematic, due to acid condensation, which leads to severe corrosion, and due to fouling from soot, dust and salts.

The idea

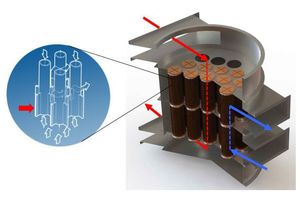

In close cooperation with the Dutch Technical Centre for the Ceramic Industry (TCKI), a new polymer-based technology for heat recovery has been tested at two brick production plants, at the brick manufacturers Rodruza and Engels Baksteen in the Netherlands (»1).

In the plant trials that lasted twelve months, it was investigated under which conditions and in which manner heat can be recovered from corrosive flue gases. In both trials, the impact of the process conditions on the materials used for construction of the exchanger has been evaluated. At the Rodruza plant, the flue gas is untreated and therefore quite problematic. Engels Baksteen does have a flue gas cleaning system.

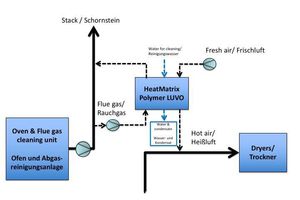

»2 shows the integration of the heat exchanger in the existing configuration. The exchanger has been positioned in a bypass, parallel to the existing flue gas duct, which means that only two tie-ins into the existing duct are needed. Separate fans are installed to avoid disturbing the pressure balance of the kiln itself.

Results

The plant trials gave the following results:

The heat recovery realized matches the theoretically calculated recovery

Soot, dust and salt deposits on the flue gas side are easily removed, using the installed spray-cleaning system, which is turned on briefly every two to three weeks. This avoids build-up of deposits and manages the pressure drop

The air side of the heat exchanger shows no signs of fouling

The polymer-based heat exchange bundles have shown no signs of corrosion

Conclusion

TCKI concluded that this innovative polymer-based technology from HeatMatrix enables the recovery of heat from flue gas, thereby reducing the overall energy consumption and CO2 emission in the ceramics industry. This lowers production costs and enhances the sustainability of the process and the final product.

Depending on the plant configuration and the available gas flows, a typical payback time in the range of three to five years is possible.

www.heatmatrixgroup.com