Heat recovery with flue gas heat exchangers on ceramic kilns

The cost of energy is on the rise, so it is becoming increasingly important to prevent energy losses and practice sustainability. Numerous ceramic kilns still have such high levels of flue gas heat losses, that it would be a thoroughly worthwhile investment to fit them out with heat exchangers. This contribution presents several completed projects as examples.

1 General

Hot flue gases from ceramic kilns can rarely be directly exploited as heat sources for other parts of plant, because they are always more or less heavily contaminated with undesirable constituents from the raw materials and/or fuel. While some brickmakers actually do make direct use of flue gases in their drying facilities, the acidic content of the gas is not very good for either the dryers or the drying supports and stillage. Consequently, heat exchangers are needed to extract the – often quite substantial – thermal energy from the flue gases.

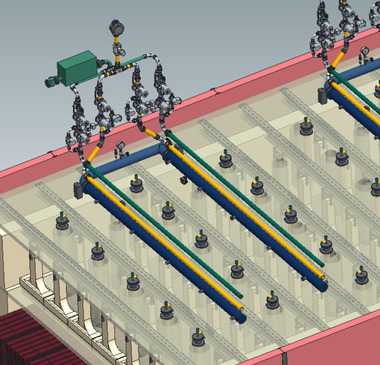

Heat exchangers can operate on air,...