Improving OEE for higher productivity and future-proof assets

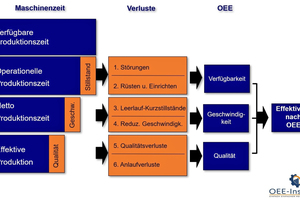

Is an OEE analysis worth-while?

Heinz-Joachim Schulte, founder of the OEE institute in Much, has the answer: “According to my own analytical experience, doubling the productivity of most machines is a fully realistic expectation. So, it is certainly worthwhile to analyse the production process.” In that sense, it should be kept in mind that machine productivity accounts for as much as 60% of a plant’s operating profits.

In the course of his career, Schulte has witnessed the closure of numerous production sites in sectors ranging from mining and steelmaking to Opel and Nokia in Bochum, to name just a few. Most consumer electronics, clothing and photo technology now hail from outside of Germany, whereas, for a long time, the respective German companies counted among the best in the world. Now, the OEE founder and consulting engineer is striving to protect major industries in the construction and construction-related sectors from such an exodus. “According to one study”, he says, “a mere 10% gain in productivity can save a company from having to relocate its production.”

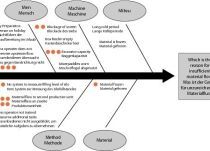

The OEE institute’s partners are a group of technical retailers in the German-speaking D-A-CH area (Germany, Austria and Switzerland). They have organized themselves within the VTH Verband Technischer Handel e.V. (technical retailers association). As experienced industrial service providers, they look after and maintain the technical equipment and installations at numerous industrial plants. They keep tabs on the machines’ respective degrees of utilization for automated series production and can always call in Heinz-Joachim Schulte’s team for some additional expertise. The following example illustrates the potential extent of savings: A machine operating around the clock has to be shut down for 20 minutes on each 8-hour shift to enable manual replacement of a full container. That adds up to one hour per day. A technical-retailer analysis, though, yields an ultimate annual savings potential of € 252 000.

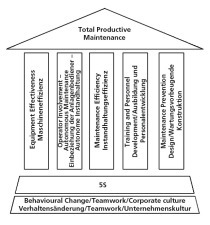

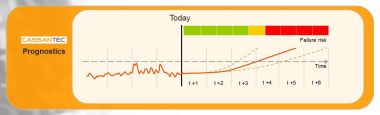

OEE monitoring is recommended as a basis for predictive maintenance as well as for any the other maintenance strategy.

www.oee-institute.de