Influence of the atmosphere on the tunnel kiln

process

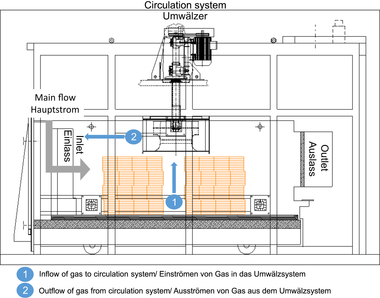

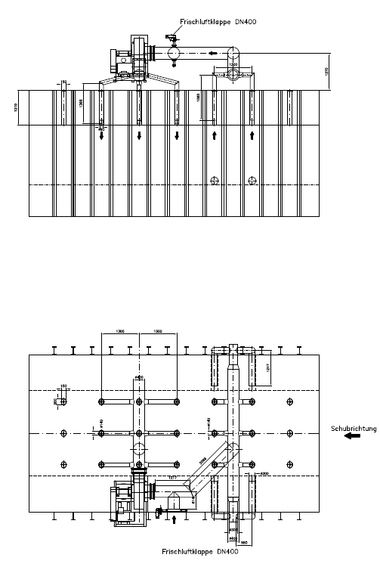

In the making of clay bricks, the firing process is particularly important. It crucially influences the product quality as well as the costs of the overall process. To ensure a uniform transfer of heat, besides flow homogenization in the firing channel, achieving a uniform kiln atmosphere is important for product quality.

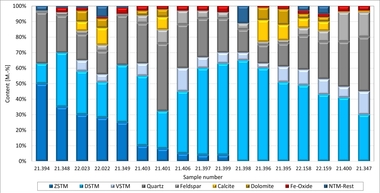

The composition of the gas atmosphere can be determined relatively easily from the type of primary fuel and its analysis data. The gaseous reaction components, on the other hand, are very varied in their nature on account of raw-material-related factors and thermal reactions. The volume of these components cannot be derived directly from the characteristic data of the raw materials. During gas-forming raw material reactions, for instance, hydrocarbons can be formed as a result of low-temperature carbonization processes. These adversely impact the course of the firing curve and require post-combustion on account of their association with pollutants. In addition, at low flue gas temperatures, they can be accompanied by deposits.

In certain temperature zones, raw-material-related decomposition reactions impair the firing chamber atmosphere. These can, for example, take place parallel or contrary to the formation of carbon dioxide caused by the firing off of organic components. The thermal effects on the firing process and emission-relevant influences will be described, the mutual interference also being addressed. Not least, the firing chamber atmosphere influences the energy consumption.

Dipl.-Ing. E. Rimpel, Brick and Tile Research Institute Regd, Essen