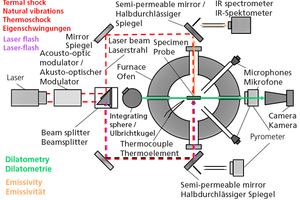

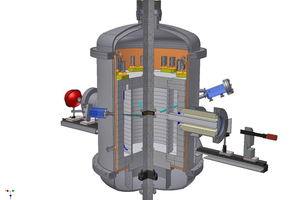

Innovative ThermoOptical Measuring Devices (TOM) for high-temperature testing of refractories

Refractories are the key for the development of new energy efficient thermal processes. Existing deficiencies in their high-temperature characterization are closed by a new generation of ThermoOptical Measuring devices (TOM). Using the new methods enables the characterization of thermochemical and thermophysical material behaviour under defined conditions up to temperatures of 1800° C. By that, new refractories and thermal processes can be developed more purposefully.

1 Challenges for new refractory products

A large proportion of all energy consumed in the manufacturing industry goes for heating processes: In 2016, some 1700 PJ (1 PJ = 1015 J) of process heat was expended in the Federal Republic of Germany. More than half of that total served for driving thermal processes involving temperatures beyond 1000° C. That alone accounts for approx. 20% of Germany’s total rate of end-use energy consumption [1]. Of course, numerous other heating processes are also involved, most notably in terms of power generation and private heating systems. If the climate...