Marcheluzzo Ceramic Division: When theory turns into practice

Marcheluzzo Impianti is a byword for top quality and years of experience in turnkey plants for manufacturing clay building materials. With the expertise it has amassed, Marcheluzzo Ceramic Division can offer solutions for the following industry sectors: sanitaryware, ceramic insulators, refractories, vitrified clay pipes, façade tiles, Technical ceramics, ceramic catalysts, architectural terracotta, ceramic plant pots, plaster products and clinker bricks.

Casting and slip systems: Marcheluzzo Ceramic Division supplies a microclimate control system for a wide range of casting processes, which can be adapted to the specific casting system. For heating casting slip tanks and control of the slip temperature, Marcheluzzo Ceramic Division uses various technologies: from hot water circuits inside the agitators through jacket heaters to the installation of coaxial pipe heat exchangers. The Marcheluzzo experts develop solutions for every problem in drying and surface hardening to the leather-hard state

Dryers: For the different ceramic manufacturing processes, Marcheluzzo Ceramic Division supplies the following solutions:

Multi-sector tunnel dryers in which the thermodynamic phases are obtained from the mechanical pushing of the dryer cars, designed for automatic handling lines with a continuous flow of products

Chamber dryers with homogeneous low-speed ventilation and high air recirculation, to meet the configured parameters with high precision, These are especially suitable for the production of specials in small quantities, for drying plaster moulds, insulators, or refractory materials

These dryers are designed to adapt the air velocity and direction of air in order to maximize efficiency. The fans are equipped with frequency inverters to ensure the air flows around the products from different directions.

When the theory turns into practice, everything starts with the Marcheluzzo laboratory. The Ceramic Division has an extensive array of testing equipment for various analyses. In addition, drying simulators can be set up at the customers’ facilities so as to involve the customers’ technical staff and simulate a range of working conditions. Dryers can then be developed that meet the specified performance requirements.

Handling systems: Integrated handling systems for all stages in the production processes are essential for modern industrial manufacturing of ceramic products. A high degree of automation increases the product throughput, while reducing the labour requirement and the quota of reject products

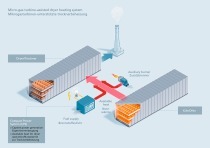

Thermal plants – energy recovery: When more than one plant needing thermal energy are concentrated in one facility, an effective solution is a centralized system based on hot water as an energy carrier. The heating system supplies hot water in the right quantity, temperature and pressure to all exchange circuits. Marcheluzzo uses only boilers, pumps and burners from well-established manufacturers to ensure the best customer service and reliable supply of spare parts all over the world

In response to steadily rising fuel prices, Marcheluzzo offers an energy recovery system that utilizes thermal energy from the kiln for heating water and feeds this to the hot water circuit of the centralized heating system. In the case of continuous kilns, waste heat from the cooling air is used to obtain 90° C hot water. To avoid acid condensation, hot water at 120° C is used. The same type of energy recovery at 120° C is possible with batch kilns. Taking the firing into consideration, a specific algorithm has been developed to maximize performance at all times. The system is designed to avoid any internal depression either in tunnel kilns or batch kilns.

Engineering: Marcheluzzo Ceramic Division generates 3D models of complete plant layouts

Hall B1, Stand 501

Hall B2, Stand 300