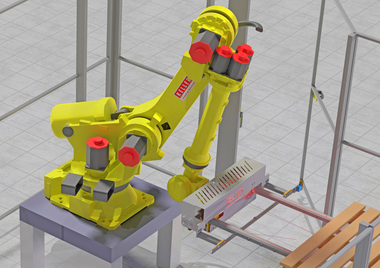

Intelligent industrial robots – system concepts with the example of a mixing plant as a standalone solution

Keller HCW develops and implements individual robotic solutions for various industrial applications. The focus is on functional solutions for the heavy clay industry. Back in the mid-1990s, Keller installed the first industrial robots and has consistently further developed this approach to this day, having installed almost 1000 robot applications.

While in the beginning it was just the idea of automation, today it is more and more also an answer to the existing shortage of skilled workers. With the continuous development of robot tool concepts (grippers) in combination with intelligent control concepts, the range of applications for robots is almost unlimited.

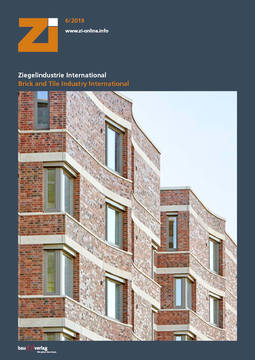

As best practice for these developments Keller HCW presents solutions for mixing facing bricks and clay pavers from different packs, so that the bricklayers only have to work from one brick pack. Another solution presented is the assembly of empty pallets in the unloading and packaging area. Empty pallets are often delivered to the factory interlocked one into the other and have to be manually unlocked and checked in a quality control. For this, Keller HCW offers a robot application with integrated quality control and automatic sorting of sub-standard pallets.

Lutz Jankowski, Keller HCW, Ibbenbüren