K-Matic Moisture Control – Online moisture measurement

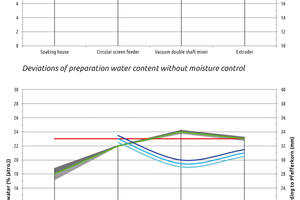

In the continuous production process of material preparation and shaping, you receive a fast and clear response when specific parameters are actively changed. In practice, however, it is not that simple. For example, wear and tear, changes in the delivered material, its varying moisture content and unplanned production interruptions may lead to variations in the production process, which have a direct effect on the product quality.

With the analysis of material samples, preventive maintenance work and the experience of the operators, countermeasures can be taken in time and the desired quality can still be ensured. However, experience gained over many years cannot always simply be transferred to a new employee and this may result in incorrect assessments.

Continuous measurement of the input moisture

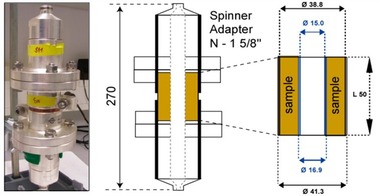

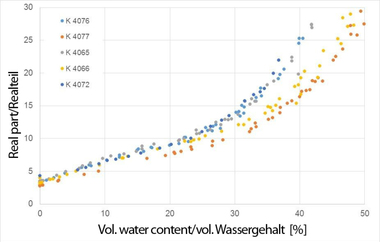

With the new K-Matic Moisture Control Keller offers the operator a simple possibility to permanently monitor the changes in the preparation water content by continuous measurement or indication of the measured value and to react directly to them – without waiting for a moisture analysis, which, moreover, only reflects the condition of the material at the time of sampling. Furthermore, clear measured values enable even inexperienced operating personnel to react adequately to variations in the preparation water content.The measured value can be transmitted and evaluated both analogue and digital through various interfaces. This also allows automation of the required water addition.

At the KDW clinker roof tile plant of the ABC-Klinkergruppe at the Natrup-Hagen site, for example, the implementation of the K-Matic Moisture Control in the production of roof tiles and accessories has further improved the production processes and therefore the product quality. By the continuous measurement of the input moisture of the operation mass delivered from the central preparation plant, the required addition of preparation water can now be controlled more precisely, so that an even more constant operation of the shaping lines is achieved. „This is an investment that one would no longer want to do without,“ says Klaus Kuhlmann, the Plant Manager. „The improved efficiency in the production process is also reflected by the reduced waste rate.“