Long-established company repositions itself

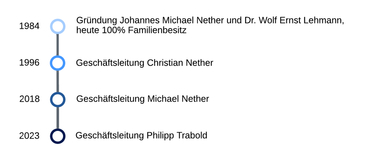

Since 2020, Thermoplan GmbH has been repositioning itself, both with regard to its personnel and business focuses, as the company informs us. Its goal was to extend its established expertise and dependability to many more areas in order to provide comprehensive support to its customers in the heavy clay industry in future.

The established core expertise areas of process engineering, control technology and automation have been given a boost with new, but very experienced employees. New areas have been opened up with the help of new employees and a generation change has been heralded in the company management – as a basis for long-term dependability .

As a result, along with its other focuses, the very topical issue of energy saving is now met with a great deal of experience and passion in the company, says Thermoplan. Thanks to several cooperative ventures with other companies, it was possible to cover the entire spectrum of brick plant requirements and offer dedicated solutions. This now included mechanical service.

Besides the core areas of control and process engineering, process optimization/energy saving and automation, the areas of expertise currently established at Thermoplan include plant engineering/robotics, 2D and 3D camera systems, platforms and vehicle groups, the “Bluebox” quality inspection system, project development, training, safety, CE certification, support with audits of all types, electrical and mechanical servicing, as well as replacement and wear parts.

Control technology & process engineering – process optimization/energy saving

For more than 30 years, Thermoplan has been a partner to the clay brick and tile industry, offering process optimization and control technology for thermal processes. As a basis for process control, plant analysis and benchmarking, Thermoplan has been committed from the start to a comprehensive software solution covering process engineering, operational and energy data acquisition as well as quality assurance. The software is continuously upgraded so as to remain state of the art, Thermoplan promises.

Automation

Professional switch cabinet engineering, latest control technology and sensors/actuators combined with sound know-how in safety engineering provide key elements in Thermoplan’s automation projects. A special feature of its work is the fast rebuild of machines and production processes as part of retrofit projects.

Customized software design and user interfaces has become more and more important in recent years, says Thermoplan. For this reason, the company supplies software concepts driven by consultation with customers, adapted to their maintenance needs and preferences.

Plant engineering/robotics,

platforms and vehicle groups

Plant engineering/robotics has been included in the Thermoplan portfolio of services for many years. New since 2021 are platforms and vehicle groups. The first dryer platform went into service in January 2022, says Thermoplan.

‘Bluebox’ quality inspection –

2D and 3D camera systems

State-of-the-art camera systems as well as 2D and 3D laser scanners are used by Thermoplan in a wide range of projects. Whether in full automatic control of roofing tiles by means of the Bluebox inspection unit, or as support for robot positioning, capture of brick dimensions in the grouping of facing bricks or as read stations for kiln car coding, this expertise can be used in extensive potential applications, as Thermoplan promises. Equipment featuring camera systems for production monitoring and support has already been installed by Thermoplan in a number of plants.

Project development – training

Customized maintenance training was established by Thermoplan as a product years ago, but project development for diverse projects and plants has now been added as a new service. In this context, the Thermoplan approach focuses on designing low-maintenance plants with maximized efficiency and refining these together with the customer. New in the portfolio is project management for a wide range of investment projects.

Safety – CE certification – support with audits of all types

Thanks to successful recruitment of specialist personnel in 2022 (a senior-level mechatronics engineer and a master electrician with relevant experience in plant and operational safety as well as process and product audits), Thermoplan is equipped to carry out complete CE certification of plants, serving as a contact partner for all questions on plant safety. Moreover, Thermoplan offers support with preparations for a wide range of audits.

Electrical & mechanical servicing – replacement and wear parts

In addition to electrics and control service, mechanical servicing is new in the portfolio. Experienced operatives are also on hand for the procurement of replacement and wear components, for both electric and mechanical assemblies, says Thermoplan.

Range of customers

In the following, Thermoplan references some of the customers it has provided with extensive support in control technology, process engineering and plant engineering over the last two years and will continue supporting in the future:

ABC-Klinkergruppe – Three of the ABC-Klinkergruppe facilities have been equipped with process engineering in the form of control systems and operational data acquisition. At two sites, the complete control technology has been upgraded by Thermoplan in recent years.

Deppe Backstein-Keramik – Over the last five years Deppe Backstein has realized a comprehensive reorganization of its production site, comprehensively supported by Thermoplan in all areas – from automation to control technology.

Eder Ziegelwerk Freital – At the Freital brick plant, since winter 2020/2021, the plant control system has been installed and0 80 % of control systems upgraded. The process optimization has had a considerable impact on product quality and efficiency, for instance thanks to plasticity regulation in product shaping.

Hörl & Hartmann Gersthofen and Bönnigheim – For fully automatic roller shutter box production at the Gersthofen site, Thermoplan is supplying the control and line management system in 2022. In addition, the company has been supporting the Bönnigheim site since autumn 2021 with process engineering and automation solutions for almost all production lines

Klinkerwerk Iking – In recent years, Klinkerwerk Iking has undergone modernization by the customer working together with Thermoplan. This included rebuilding the setting station (robots), process engineering/automation and optimization of the presses (plasticity regulation).

Jacobi Langenzenn – The Langenzenn site has been supported by Thermoplan for years in many areas, e.g. diverse automation projects, supply and installation of control systems for many of the production lines and commissioning of the Bluebox quality inspection station for automatic full inspection of roofing tiles at two lines in 2022.

Vandersanden – Oberlausitz brick plant - In winter 2022/23, Thermoplan will equip the Vandersanden Oberlausitz site with control technology for kilns and dryers as well as data acquisition. With regard to plant automation, several control systems will be upgraded.

Thermoplan

auf der ceramitec 2022

» Halle C3.412