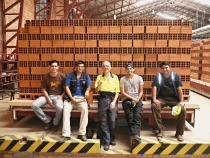

Marcheluzzo Impianti in Brazil

Since 2012, Marcheluzzo Impianti has been working intensively on an investment project in Brazil and has set up a locally based company Bonfanti-Marcheluzzo in order to break into the market with equipment made in Brazil using Italian technology. This philosophy has allowed Marcheluzzo to diversify the company’s standard market. The results show that it was a good decision: After three years of intensive work, the business division reports contracts worth around € 7 mill. annually. Production is located in Leme near Sao Paolo.

Ceramica Forte

The new “Drying Technology” department has recently developed a new semi-rapid drying process. The objective was to achieve a drying cycle shorter than three hours for hollow products and roofing tiles and less than eight to nine hours for blocks and heavy tiles, with the capability to handle all types of raw materials used worldwide. The big advantage of this project is the massive saving in thermal energy consumption. Thanks to a modular system, the production capacity can be adapted to all other requirements. The output ranges between 100 and 1400 t/day. Temperature and humidity control is performed on every second car.

The new dryer has been installed at Ceramica Forte and is running coupled to an automatic handling system for loading and unloading the dryer cars. The drying cycle takes 6.5 hours for drying roofing tiles, with an output of 33 000 tiles in seven hours. The first phase in this project has been completed and start-up was in April/May 2015. With the second phase, scheduled for April/May 2016, a final output of 120 000 to 150 000 roofing tiles per day will be achieved.

Telhamar

Roofing tile plants have always been one of Marcheluzzo Impianti’s specialities and the company has built plants for all types of roofing tiles and accessories with all kinds of technologies all over the world.

In Teresina near Telhamar, a special device has been installed for automatic checking and sorting of tiles, together with a special handling system and a robot that straps packs of 1 m, which are then loaded directly onto the kiln cars. The system is designed to work with Roman and Portuguese tiles during the day and American tiles at night, which gives the factory great flexibility. The maximum output is 6 000 tiles/h.

Ceramica Citade Nova

Thanks to its know-how, Marcheluzzo has developed very flexible lines for unloading cars and loading kiln cars for the production of blocks and hollow bricks. The output here reaches up to 500 t/day. The client’s specific requirement was the capability to frequently change the product with no time loss. This plant was built completely in Brazil with Italian technology. It is ready for delivery and will be started up in the second half of this year.

Ceramica Constrular

This project comprises a line for loading and unloading blocks and for forming packs. The very flexible line is designed for a production of 300 t/day, with continuous change of product, but without any time loss. This automatic line was built completely in Brazil.

Ceramica Lorenzetti

This client has renewed his confidence in Marcheluzzo as he is very satisfied with the installation of the handling lines set up last year, which have now been running continuously for 18 months, 24 hours per day. Now the client intends to upgrade another section of the plant with the installation of two new loading lines and an electronic cutter supplied by Marcheluzzo. These machines are also being built completely in Brazil.

Ceramica Guarany

Here Marcheluzzo is supplying an automatic loading line for wet products and an electronic cutter for an output of 400 t/d. These machines are also being built completely in Brazil.

Ceramica Cireneo

The scope of supply includes an automatic line for unloading the cars and forming packs for firing in intermittent kilns. The project will see the realization of a machine capable of forming packs on the ground with any type of material. The packs are taken by a forklift for loading into an intermittent or Hoffmann kiln. This machine will be commissioned at the end of this year. Its efficiency will make it revolutionary for local manufacturers.

Marcheluzzo Impianti S.r.l.

www.marcheluzzo.com