New and old cast qualities for clay grinding

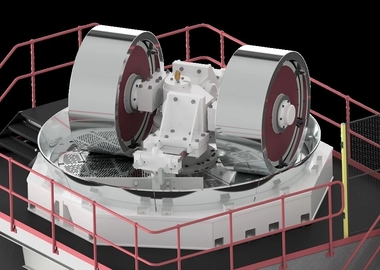

Runner rings for pan mills or roller shells for clay grinding are exposed to severe mechanical wear so that they have to be made of special materials. Besides higher wear resistance, low-cost fabrication plays a crucial role. Karl Buch GmbH manufactures roller shells and pan mill rings in an optimized casting process using specially adapted moulds with customer-specific metallurgical composition. As a low-cost but at the same time high-performance material, alloyed chilled cast iron is used. Even longer lifetimes are achieved with chromium steel. These products are manufactured individually in static casting.

As a further development, composite roller shells can be cast by means of centrifugal casting, e.g. made of chromium steel/grey cast iron or spheroidal graphite iron. Such composite roller shells are used, for example, for grinding ores.

Dr. Christian Zybill, Karl Buch GmbH & Co. KG