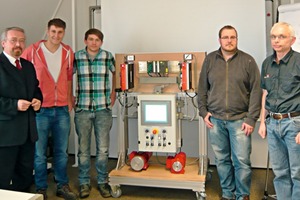

Prospective technicians at the vocational school in Osnabrück develop new drive station at Keller HCW in Ibbenbüren

This exemplary project work of the future technicians will be of great benefit for future drive technology training for customer operating personnel at Keller HCW. A mobile training wall shows two drive systems which Keller HCW frequently uses in its plants. These systems can be alternately controlled from an operating panel on the control cabinet. A touch panel, also located on the control cabinet, continuously displays the current motor values. The necessary visualization was also created by the project team. In addition, the motors can also be operated by a PLC control system. All inputs required for motor control are made on the touch panel. To comply with safety issues, the installation is provided with an emergency stop facility that shuts off power to the motors.

The customer training aims at providing the operating personnel with the know-how they need for maintenance purposes, and, if necessary, with the knowledge to enhance the control programs of their plant. Therefore, the training wall is of modular design where individual equipment can easily be exchanged and thus the installation and the training itself can always be kept up to date. With their final exam project at the end of their term for which they were awarded the top grade of 1.0, the future technicians could put their acquired knowledge into practice and get a first impression what to expect in their later career.