Reduction of “alkali bursting” in tunnel kilns with an

alkaline suspended roof

Refractory systems for suspended roofs constitute a sensitive kiln area and therefore need to be adapted to the prevailing firing temperatures and kiln atmospheres both in terms of their construction and material composition. A particular challenge is the reduction of corrosive wear due to “alkali bursting”.

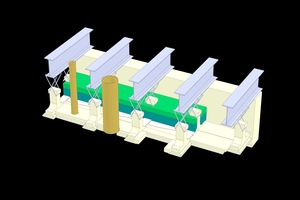

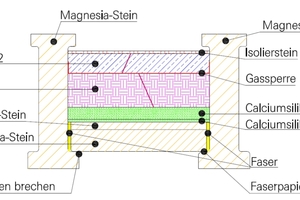

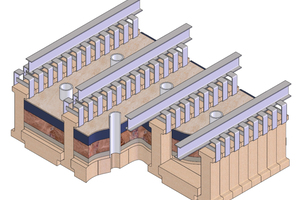

The Refratechnik Group has developed an alkaline suspended roof to reduce ‘alkali bursting’. The starting point for the development was the high alkaline level in the company’s own tunnel kiln in Göttingen. Suspended roofs and walls were already heavily corroded. The structure of the preheating, heating and cooling zones corresponded to the wall and roof constructions typical in the brickmaking industry. The suspended roof discussed below consisted of suspended and intermediate bricks as well as several insulating layers, the suspended bricks and roof girders being connected with roof clamps (...

![»2 Infiltrated damaged kiln roof in the area of the heating zone, duration 6 to 7 years [1]](https://www.zi-online.info/imgs/1/5/3/0/6/5/6/tok_ae25201cc6bad149419782d085311e2b/w300_h200_x600_y450_Refratechnik__2-82b0b69ad66302a1.jpeg)

![»5 Suspended roof bricks: high-alumina brick (left), magnesia brick (right), [1]](https://www.zi-online.info/imgs/1/5/3/0/6/5/6/tok_268950dcfbdb96ffb4d8ca46b502030f/w300_h200_x600_y702_Refratechnik_5a-0d7aa64cc290677d.jpeg)