Roofing tile manufacturer saves almost € 5 000 annually by using linear guides

with lubrication unit

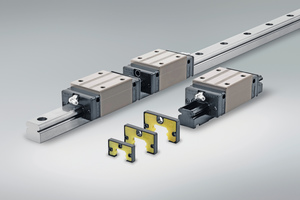

A roofing tile manufacturer approached rolling bearing manufacturer NSK with the request to increase the service life of the linear units on six handling systems. As part of the Added Value Programme (AIP), NSK specialists inspected the linear systems and environmental conditions and found that both the lubrication and sealing of the units needed to be improved. NSK recommended the use of linear systems with the K1 lubrication unit, and the manufacturer put this recommendation directly into practice. The K1 unit improves sealing and prevents contaminants from entering the inside of the linear system. In addition, the reduced wear means that the preload is maintained over a longer period of time. Thanks to the reduced friction, the drive pressure of the pneumatic cylinder was lowered from 6 to 4 bar, which saves energy costs.

With the use of the K1 lubrication units on the six systems, the previous total of 52 relubrication processes per year, each of which took 30 minutes, could be reduced to two, resulting in a cost saving of € 4 950 per year.

NSK‘s lubrication units have been specifically designed for long-term lubrication. The K1 unit was first introduced in 1996. Since December 2019, users have also had access to the further developed K1-L, which allows even longer maintenance-free operation of the linear units. Thanks to a new resin, twice as much oil can be stored, which is slowly released. The new design of the K1-L reduces the dynamic friction during the linear motion of the LM block by about 20%. The new K1-L housing increases the rigidity of the lubrication unit and helps to effectively prevent contaminants from entering the guide block.

NSK Europe

www.nskeurope.de