Sabo modernizes packaging line at Ibstock’s South Holmwood facility

The scope of the project was the replacement of the existing equipment with a new robotic packaging line. Before the modernization, the plant was using an outdated robotic system that was adversely affecting the quality of the final product. Moreover, the frequent stoppages of the old equipment were limiting the capacity of the line and the entire plant.

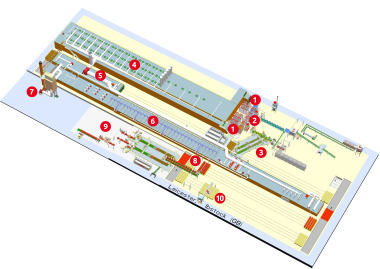

New packaging line

The new system was designed to be simple and reliable ensuring minimum stress on the final product and the creation of robust final brick packs.

In this new packaging line, one new robot takes the layers of bricks from the two existing programming benches and builds the final pack on a new roller conveyor. An additional spacing mechanism was added as an extension of the existing programming and sorting bench to replace the old slow stand-alone mechanism. The spacing mechanism creates the third layer with the suitable openings for lifting of the pack by a forklift.

After the pack is formed, it is transported on the roller conveyor to be strapped and consequently hooded by a stretch-hooding machine. While being strapped, the formed pack is supported at the sides to ensure effective strapping. The vertical strapping machine works in combination with a heavy-duty pusher that ensures the accurate step-by-step movement of the pack at the four strap positions. During strapping, plastic angle protectors are placed at four edges of the final pack. The pack is then passed onto the hooding station, lifted and hooded. Lifting ensures that all eight corners are covered by the hood.

Finally, the finished pack is passed to a chain conveyor to be picked up by the forklift.

Focus on safety

Special attention was given to safety in the design of the line. All barriers and access platforms provide a safe working environment for the operators while enabling at the same time good access to the machines. An analytical risk assessment study was performed to guide the selection of the equipment and the design.

In terms of implementation time the project was quite challenging since all the work including dismantling of existing equipment, installation and final commissioning of new machines had to be completed in a period of less than three weeks. The project was delivered in accordance with the planned timetable and met all the requirements for quality, safety and production standards.

www.sabo.gr