Bongioanni’s success in the Chinese façade panel market

The Province of Fujian located on the southeast coast of China is an important centre for the Chinese ceramics industry. Over the last few years, the ceramics industry in this province has grown steadily thanks to the introduction of a wide variety of rear-ventilated façade panels onto the market. Many ceramic manufacturers based here have invested substantially in the modernization of their production lines. Here they rely on the experience and outstanding technical solutions offered by Bongioanni Macchine in Fossano.

In 2009, for instance, Bongioanni was able to realize its goal by installing and commissioning a first extrusion line in line with the contractually agreed schedule at one of the most important and renowned factories in this province. This first order was for an extrusion line for the production of facade panels.

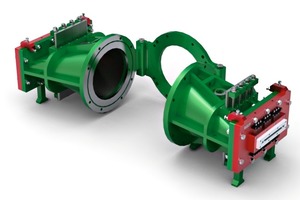

The machine supplied by Bongioanni Macchine is a Tecno 450 extruder, equipped with RAV, the patented electronic extrusion control system. With this equipment, a much lower extrusion rate can be obtained compared to the standard extrusion rates of these machines. With this slower rate, the stresses transmitted to the clay panels and the energy consumption are reduced. This allows the operators to concentrate on the quality control of the extruded product, relieving them from the continuous adjustment they were obliged to do on the previously installed equipment.

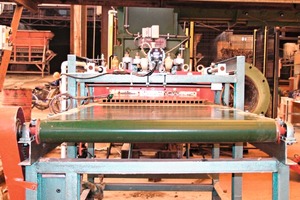

Furthermore, Bongioanni Macchine and its subsidiary Bongioanni Stampi have cooperated to re-design the extrusion pressure heads and dies for the Chinese customers, in order to improve control of the extrusion of the rear-ventilated façade panels and to make the extrusion process more reliable. With the help of this system, the quality of the final product has been significantly improved at all the manufacturers of façade panels supplied with Bongioanni machines in the Fujian Province.

All these manufacturers also provide excellent reference projects for the Chinese market.

Rosario Palumbo

In 2009, for instance, Bongioanni was able to realize its goal by installing and commissioning a first extrusion line in line with the contractually agreed schedule at one of the most important and renowned factories in this province. This first order was for an extrusion line for the production of façade panels.

The machine supplied by Bongioanni Macchine is a Tecno 450 extruder, equipped with RAV, the patented electronic extrusion control system. With this equipment, a much lower extrusion rate can be obtained compared to the standard extrusion rates of these machines. With this slower rate, the stresses transmitted to the clay panels and the energy consumption are reduced. This allows the operators to concentrate on the quality control of the extruded product, relieving them from the continuous adjustment they were obliged to do on the previously installed equipment.

Furthermore, Bongioanni Macchine and its subsidiary Bongioanni Stampi have cooperated to re-design the extrusion pressure heads and dies for the Chinese customers, in order to improve control of the extrusion of the rear-ventilated façade panels and to make the extrusion process more reliable. With the help of this system, the quality of the final product has been significantly improved at all the manufacturers of façade panels supplied with Bongioanni machines in the Fujian Province.

All these manufacturers also provide excellent reference projects for the Chinese market.

Rosario Palumbo