Optimal size reduction with roller crushers by Händle

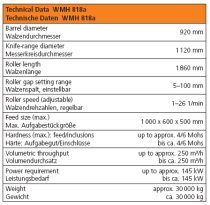

Händle makes two basic types of roller crushers: WMH with hydraulic drive and WMM with mechanical drive. The WMM models have advanced drives with modern conical spur gears and flanged-on motors. An interposed clutch that separates motor and gearing in case of an overload ensures very good operational safety and reliability. This also makes the drive assembly much more compact than before, with its previously employed type of coupling and belt drive. For raw materials containing substantial amounts of hard rock inclusions, reverse mode is recommended, and hydraulic crushers are particularly good at that. As soon as a certain, preset torque is exceeded, both rollers automatically go into reverse. The rock causing the overload is forced into a different position, making it easier to split and crush. The mechanical roller crushers can also be designed for reverse-mode operation. All they need is a variable-frequency motor. The standard version needs no such motor, because roller crushers are normally operated at a constant speed of rotation.

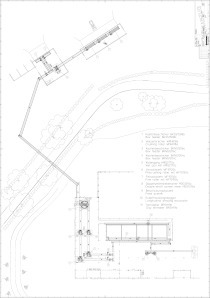

The size of the crusher depends on the throughput and on the nature of the mill feed. Each crusher comes mounted on a base frame for easy installation. A number of options are available for optimal customerization.