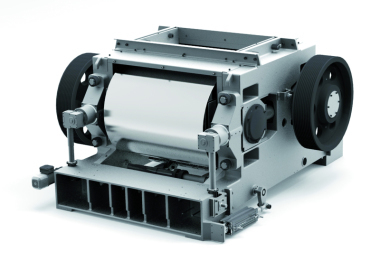

High-performance fine roller mill Alpha II by Händle

Händle’s (www.haendle.com ) rollout of the Alpha II in the year 2000 marked the appearance of a whole new generation of hinge-type fine roller mills for ceramic materials. Today, more than 80 Alpha IIs are in service around the world for comminuting plastic and semi-plastic raw materials.

What makes Alpha II roller mills so special is, for one thing, that they allow a roller-gap setting of 0.35 mm and, for another, that they are able to indefinitely maintain an effective roller gap of 0.5 mm under load. In the course of constant product innovation, the Alpha II roller mills have been equipped with a new control system. Now, all standard models come with a Siemens S7 automation system featuring a Siemens standard Color Touch Panel TP 177B plus Ethernet connection, hence enabling hook-up to the company‘s local computer network. Users of Siemens standard software have access to and can communicate with the control system. The single-rocker roller-gap adjusting assembly has also been improved by addition of two threaded spindles and gear motors. The prior approach to roller-gap adjustment by way of tachometric measurements has been replaced by precise adjustment based on direct position sensing via a linear scale on the spindle.