Capaccioli presents Super Fine roller mill

The first two complete clay preparation lines have been installed, one at a stove tiles factory in Romania, and the other in Algeria, for the Amouri Group. The Algerian plant was designed completely by Capaccioli for a production capacity of 400 000 tonnes/year hollow bricks. Moreover, Capaccioli has begun with the delivery of a completely new plant for an annual production of 200 000 t hollow bricks to another major Algerian brick manufacturer. With this project, the Capaccioli Group will have supplied three turnkey plants to the Algerian market within one year.

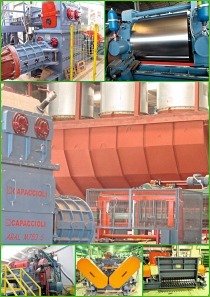

All clay preparation and production machines of the brand new Aral series line are manufactured by using the most advanced 3D CAD design techniques, combining simplicity with rugged construction. Depending on the type of clay used, the customer can choose different machines in terms of capacity and preparation of the materials. The product range extends from box feeders, through disintegrators, crushers, mixers, standard roller mills, and fine roller mills to extruders with augers up to 750 mm in diameter.

A highlight in the new product line is the Super Fine roller mill, specially developed for customers who use clay with high carbon content. Capaccioli is one of few companies designing and manufacturing this machine completely in their own factory. The total weight of the smallest version, model LF 1008, is about 60 t. The roller mill is equipped with a mobile cylinder installed on a double swinging arm, permitting very fine milling, down to 0.6 mm with a production capacity of 18 t/h.

This implementation of know-how crowns Capaccioli’s technological growth, without subordinating the traditional high-quality production of automatic robotized installations, dryers and kilns. With the recruitment of highly qualified specialist personnel, the company has strengthened its different departments.