Latest-generation strapping machines from Gerd Mosca AG use ultrasonic sealing technology. In everyday practice, that can reap a number of advantages. Convinced of this, Creaton AG obtained several such strapping machines with the new ultrasonic sealing units for their plant in Wertingen.

Fast, maintenance-saving and service-friendly

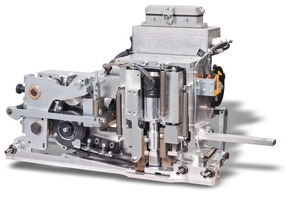

Since the ultrasonic sealing units (»1) need no heatup time, faster cycle times are achievable, no vapours or odours are generated, and ultrasonic sealing systems are very economical: Only during the actual sealing operation is any energy needed, because, unlike the hot-wedge method, ultrasonic sealing requires no particular temperature. During electric hot-wedge sealing, residue and stickiness consistently accumulate on the welding tongue, where they lower the quality of the seal and necessitate additional, usually unplanned maintenance work. Ultrasonic sealing also offers advantages over the customary kind of friction-weld seals made by most pallet strapping machines. It is not only faster, but also generates neither dust nor grit that could collect in the equipment. Moreover, the machines are much less noisy.

Ultrasonic sealing units are powered exclusively by brushless, practically wear-free, direct-current drives characterized by markedly high efficiency. That lowers energy consumption, and the direct-drive configuration reduces the number of otherwise required mechanical wear parts, hence helping to minimize the overall maintenance requirement. To top things off, all moving parts are equipped with robust, long-lasting ball bearings.

Inline strapping machines for individual packages

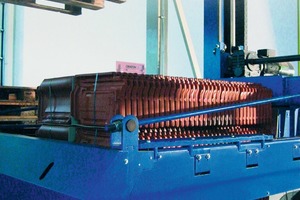

Each of the two productions lines for “Harmonie“ series standard roof tiles at the Wertingen plant now has two type-MK 44 strapping machines integrated into their automated line-up (»2), where they attend to the strapping of individual packages. They were specially modified for this particular application, in which they wrap highly elastic, 8 mm-wide PET tape around individual stacks of five clay roof tiles. Each machine includes an integrated, four-sided, automatic package aligner. Since the machines are designed for up to five packages per minute, freight securement is guaranteed not to constitute a bottleneck in the chain of production.

This also applies to the same type of fully automatic strapping machine that was integrated into the accessory line, where it straps accessory tiles (ridge tiles, verge tiles and other accessory shapes) to form individual packages of various size. The strap tension is adjustable to satisfy the respective product requirements, and the strap guide system is designed for removal and replacement for servicing without need of tools.

Horizontal and vertical pallet strapping

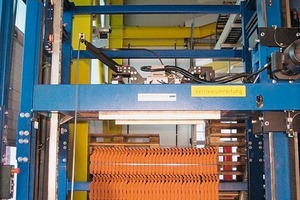

Once the individual packages have been strapped, they are stacked on pallets and secured with additional straps for further handling. To that end, both the standard-product line and the accessory line each have two fully automated pallet strapping machines. First, the palletized stacks of individual packages are strapped horizontally, layer by layer by the type-KOH-315 (»3) strappers, which are equipped with height-adjustable, horizontal strap guide pillars and a four-sided aligner. Horizontal strapping takes only about 10 seconds (package-dependent). The strap tension is infinitely adjustable between 250 and 2500 N, and the strapping height is randomly selectable via simple teach-in programming.

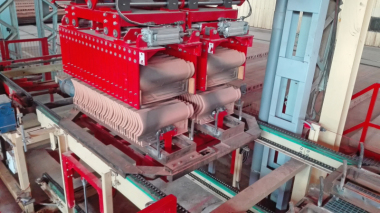

After that, the pallets have to be vertically strapped to ensure optimal freight securement. This is also taken care of by the fully automated type-KOV-112-P strappers (»4). They strap the pallet inline, i.e., the pallets do not have to be turned for vertical strapping, because strap dispensers incl. sealers situated in the pallets‘ direction of travel swing into position for strapping the packages. The laterally manoeuvrable, gantry-type machines are designed such that the bottom strap guide constitutes an integral part of the conveying system, so no strap guide lance is needed.