Hagemeister successfully tests hydrogen as the energy carrier of the future

In the brick industry, hydrogen is considered a key energy to achieve the legal requirements for climate neutrality in 2045.

Hagemeister is already working together with the Institut für Ziegelforschung Essen e.V. (IZF), KELLER HCW GmbH, Kueppers Solutions GmbH and VDEh Betriebsforschungsinstitut GmbH on the realisation of this energy transformation. Within the framework of the joint research project „Energy Efficiency and Emission Reduction - Use of Hydrogen in the Brick Industry (H2 Brick)“ - funded by the progress.nrw initiative of the state of NRW - the use of hydrogen in the serial production of the clinker plant is currently being validated.

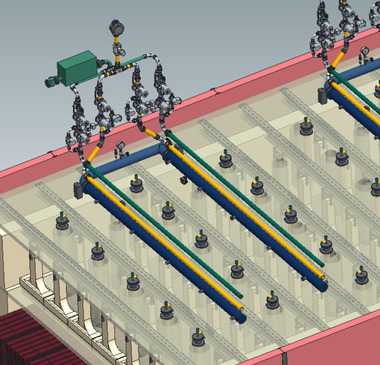

A 3-week test is currently running under real conditions, in which bricks are produced with the addition of hydrogen. For this purpose, Hagemeister has created a hydrogen infrastructure and installed the burner technology developed as part of the project.

„The first production results show that the energy source and burner technology are well suited for the production of climate-neutral clinker bricks“ reports IZF project manager Dr.-Ing. Rigo Giese.

For the clinker plant from Nottuln, the test proves that a conversion to hydrogen is possible as soon as the green energy carrier is available. „For Hagemeister, there is no alternative to switching to hydrogen as an energy carrier in the medium term,“ explains Alexander Dütz, operations manager at Hagemeister. Managing director Christian Hagemeister adds: „We expect support from politics in the expansion of the pipeline infrastructure and the availability of hydrogen at competitive prices. In addition, a set of regulations for the use of hydrogen that is suitable for medium-sized companies must be created.“

Hagemeister is not alone in this demand. An association of committed companies in the region (Hagemeister, YARA, Zinq and Dr. Suwelack) met with representatives of the North Westphalia Chamber of Industry and Commerce and the Coesfeld Economic Development Corporation during the test operation in Nottuln.