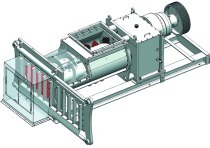

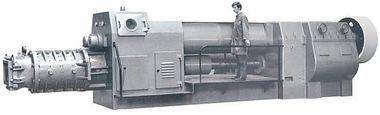

Petersen sells two extruders to Feldhaus Klinker

Back in 2008 a Petersen extruder was put into operation at Klinkerriemchenwerk Feldhaus GmbH & Co.KG, one of the market leaders in the production of brick slips. This extruder is individually matched to requirements in a mixed production operation. Those responsible at Feldhaus Klinker were surprised at this extruder as it was the first to work without any problems from the start and did not require any reworking at all.

For a second line, Feldhaus had originally planned to optimize an existing extruder with a vertical prepress and replace a double-shaft mixer from 1979. But on the strength of their good experience with the new Petersen extruder, those in charge at Feldhaus changed their minds. Contrary to the plans to simply upgrade the existing line, they opted for a forward-looking integrated solution and ordered a second extruder from Petersen. This enables faster cleaning of the machine when handling frequent body changes and makes changeover of the production lines for corner slips and slips in mixed operation much easier overall.

The new extruder not only facilitates a wide range of products, it saves up to 30% energy.