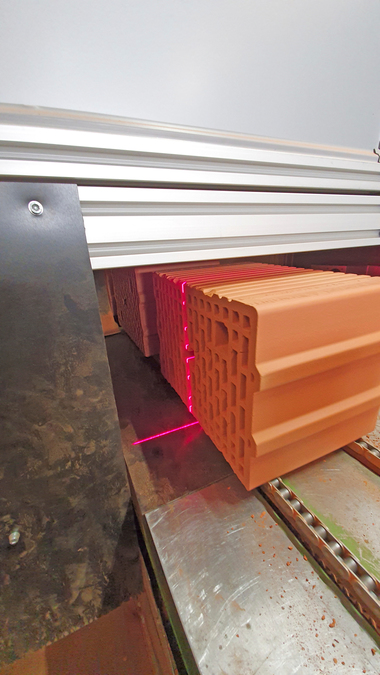

Air-coupled ultrasonic inspection of ceramics

Unprecedented accuracy and reliability in the non-destructive testing of ceramics is offered by Sonotec, according to the supplier, with a new system of non-contact ultrasonic inspection. The Sonoair R&D integrated solution consists of scanner, probes, industrial computer as well as special software. Sonoair R&D was evolved in cooperation with the Ultrasonics Research Centre (FZ-U) in Halle (Saale). For the main applications in ceramics, the compact system enables the evaluation and testing of samples for delamination, air inclusions and inhomogeneities or density fluctuations both in green products and fired ceramics.

Precision technology plus scientific support

Additional user benefits were enabled by the close cooperation of his company with the independent ultrasonic research centre FZ-U, explained the Sonotec manager: “Our partners there have many years of expertise in the scientific analysis of demanding testing applications, which we can activate at any time.” Dr Mario Kiel, Manager of the Non-Destructive Testing department at the non-profit research institute, sees the crucial advantage of the collaboration primarily in the combination of the integrated technical package with extensive knowledge-based service – “especially for critical problems”. He explained that it was possible to quickly assess the basic testability of a sample, and to adapt the technology to specific testing problems as necessary. If required, more extensive problems could be addressed in joint research projects.

Probes with piezocomposite technology

For the wide range of different analytical projects, Sonoair R&D is equipped with new, particularly sensitive CFC probes that enable precision resolution from a defect size of one millimetre. Their stable reproducibility with identical acoustic properties can be attributed to in-house production with piezocomposite technology.

With up to four pairs of probes, the system is designed both for the testing of materials and components and the in-house development of new methods. Its multi-channel capability allows high measuring speeds. The simultaneous use of probe pairs with different frequency ranges enables in addition the testing of elements with different wall thicknesses.

The associated Sonoware Basic software was developed for rapid testing in the laboratory and in industrial plants. Collected data are generally output as two-dimensional images (C scans). The results can be optimized with the filters and processors of a related toolbox. On the other hand, the Sonoware Advanced software version is intended for the development of in-house analysis and evaluation methods. It also grants full access to the raw data. On request, Sonotec offers in advance application advice, training sessions and support in the realization of technical projects.

Sonotec has announced that its portfolio is soon to be expanded with another variation, Sonoair Industrial for plant engineering companies and industrial customers who want to integrate the new system in the design of their own products.