Briqueterie Jebal El Ouest – a new challenge for Equipceramic S.A.

The company started technical discussions with all important technology suppliers in the heavy clay sector. Key requirements were the building of a state-of-the-art plant that complies with the electricity and energy consumption ratios specified by the customer. After months of discussions and optimization of the project in close cooperation with the customer’s technicians, Equipceramic, S.A. was awarded the contract.

Equipceramic projected a factory with a daily output of 1 200 t hollow bricks. It includes two cutting lines to reach contractual production rates. The bricks will be dried in a Barna dryer to ensure a high-quality end-product. The products will be fired in a hermetically sealed Gaudí kiln.

The factory will be equipped with an advanced cogeneration system for a more efficient utilization of the energy produced during the manufacturing process, obtaining significant energy savings.

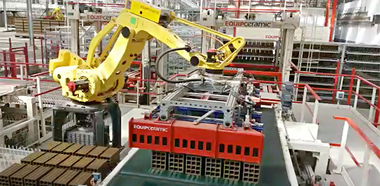

The use of sophisticated automated systems in the different process areas is also one of the most outstanding characteristics of the plant. Product handling will be entirely automated, mainly based on robotics.

Finally, the project includes a high-capacity storage area for end-products, equipped with a completely automated control and command system. A sophisticated bridge crane is used for the direct loading of dispatch packages on trucks or their storage in the yard.

With the experience from this project, Equipceramic can offer future customers even more efficient solutions with regard to workplace safety, dust protection, energy consumption and production increase.

Equipceramic, S.A.

www.equipceramic.com